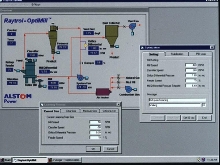

Pulverizing Mill Software learns how to control operations.

Raytrol-OptMill(TM) monitors system parameters and controls roller mills and pulverizing systems. Optimization algorithm software goes through initial learning procedure to build knowledge base for processing specific material. Using database, algorithm can determine settings to achieve maximum mill capacity and optimal energy consumption when processing particular products. Built in intelligence...

Read More »

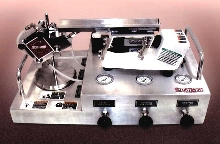

Jet Mill disintegrates particles without heat buildup.

Single Clamp MicronizerÃ-® jet mill provides narrow particle-size distribution in production of fine powders. Its single clamp encircles mill's 4 in. chamber, sealing it during operation. Able to turn out spherical particles with micron-sized diameters, Micronizer can mill up to 40 lbs of material per hour. It accepts raw materials of various particle sizes through feed funnel and replaceable...

Read More »

Multi-Purpose Mill features ultra-sanitary design.

Definer(TM) Model 2000 is fully constructed of stainless steel and measures 5 in. from inlet to outlet. Straight flow-through product path eliminates hang up or accumulation in hoppers. De-agglomerating element with teeth and combs features positive once-thru anti-clog action. Fine milling element features high shear, rotor and screen design which gently mills and conditions solids without...

Read More »

Jet Mill suits 10 to 20 gram batches.

Qualification MicronizerÃ-® with 2 in. milling chamber, can mill up to 1/2 lb of material per hour, yet is capable of feed rates as low as few grams per hour with maximum sample recovery. Fines have narrow particle-size distribution, with particle diameters as small as few microns. Replaceable venturi allows mill to accept wide range of feed sizes, and peripheral feed design prevents...

Read More »

The Importance of Sustainability in Rigid Plastic Packaging Manufacturing

Want to learn more about sustainable rigid plastic packaging? Ask the experts at CMG Plastics! We've got extensive experience in helping to bring rigid plastic products to market through complete custom plastic injection molding and blow molding services.

Read More »

Bushel Mill processes up to 5,000 bushels per hour.

Model ATG5000 mill produces precise particle size with minimal flour, dust, and waste. One-fast-roll principle provides for increased capacity at up to 1/3 less horsepower than hammer mills. Available with self-cleaning action, it is available in 4, 6.5, 8, 10, and 14 cut models. Features include self-contained hydraulics, magnetic grate in intake hopper, 14 in. intake auger, 12 in. tube conveyor...

Read More »

Small Media Mill is available with variable frequency drive.

Model QC450 uses circulation-type process, matching flow direction to centrifugal direction. Rotor creates strong centrifugal and shearing force which, when combined with fast circulation rate of slurry, increases grinding efficiency and particle distribution. With media volume of 15 liters, mill can process batches from 50 to 400 gallons at top speed of 3,000 ft/min.

Read More »

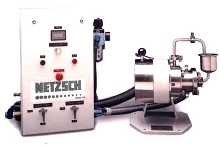

Laboratory Mill suits small batch analysis.

Portable MiniZeta is capable of handling batch sizes down to 300 mL with chamber volume of 300 mL. It is optimized for circulation or discrete pass milling. Infinitely variable speed drive works with air or electric motor. MiniZeta features tiltable chamber design and integral pumping system.

Read More »

Dry Grinders produce single micron material.

HSA Dry Grinding Attritors have side discharge screen, and media size of 1-3mm, allowing micron sized products to be generated continuously. Shaft speeds range from 400 to 1800. Devices provide dry grinding, resulting in extremely fine material. Applications include ceramic powders, glass frits, metal powders, mechanical alloying, metal oxides, fibers and celluose.

Read More »

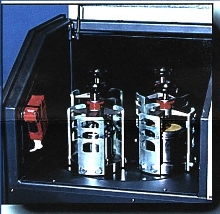

Ball Mill grinds to sub-micron dimensions.

PM 400 Planetary Ball Mill processes up to 8 samples without contamination, grinds material to sub-micron fineness, and has maintenance-free drive. Grinding sets are available in 4 sizes and 6 different materials. Superimposed motion of grinding jars, relative to central wheel, achieves high grinding efficiency. Generated energies by impact and friction of grinding media (beads) permit mixing,...

Read More »

Circulation Attritor can adapt to existing Q machines.

QL circulation grinding Attritor includes holding tank that is typically 10 times Attritor size. Specially configured arms speed up grinding and create more agitation. Unit's high circulation/pumping rate consists of holding tank contents passing through Attritor at ~8 times an hour. Grinding media for QL range in size from 3/32 to 1/4 in. in diameter. Typical media include chrome steel,...

Read More »

ISO-Certified Plastic Injection Molding from Rodon

The Rodon Group is a proven leader in high-volume, close tolerance injection molding. We offer globally competitive, innovative manufacturing solutions for a broad range of industries. Check out our video to learn more.

Read More »