Colloid Mills Reduce Particle Sizes Uniformly

A line of wet-mixing colloid mills that reduce particle sizes and provide uniform distribution for food, pharmaceutical, and cosmetics manufacturing is available from Bematek Systems, Inc. of Beverly, Massachusetts. Bematek Colloid Mills feature a milling head which has a rotor and stator gap that can be adjusted while running to efficiently achieve particle size reduction and micron dispersions...

Read More »

Impact Mill handles dry and moist ingredients.

Suited for high-speed milling, Bohle Turbo Mill BTM is attached to telescoping transport cart that facilitates movement and placement. Oscillating rotary valve feeds product into milling chamber, where reversible rotating stainless steel blade assembly reduces product particles through impact or cutting. Dry products are reduced with flat side of blade and moist products with knife-edge. Milled...

Read More »Roller Mill is designed for chemical applications.

Model 88 Chemical Gran-U-Lizer(TM) eliminates unwanted fines and provides uniform particle size utilizing continuous roller-style grinding method. Able to reduce waste and eliminate downstream classification systems, machine can be constructed with materials from carbon steel to stainless steel to meet corrosion resistance and contamination requirements. Applications include super absorbent...

Read More »

Disc-Style Coffee Grinders provide grind uniformity

Utilizing Platinum Series Burrs(TM), Series GPX Grinders produce batch sizes as small as 1 lb, and are designed to grind 350-600 lb/hour. Dial allows selection of any desired coffee grind, with end result being ability to achieve full range of grinds for variety of coffee production applications.

Read More »

5 Unique Applications for Surface Treatment Equipment eBook

The surface requirements and restrictions for components may vary from one industry to another. For this reason, components may have to undergo different types of surface treatments.

Read More »

Fine Grinding Mill prepares samples for pelletizing/fusion.

Featuring all-digital controls, Bead Mill MM 301 prepares batches of various samples to 40-60 micron fineness required for XRF/XRD and other spectral analyses results. Device homogenizes powder with wax, flux, or other binders prior to pelletizing or fusion technique. Grinding sets, available from 1.5-50 ml in metal and non-metal materials, enable typical grinding time of 2 min. Bench-top unit...

Read More »

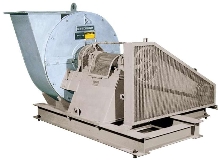

Cage Mill de-lumps and dries materials in one step.

Constructed with completely welded shell, cage mill with flash dryer handles temperatures up to 1200Ã-

Read More »

Roller Mill is designed for chemical applications.

Gran-U-Lizer(TM) IMD 1052 virtually eliminates unwanted fines and provides uniform particle size. Continuous roller-style grinding method can eliminate downstream classification systems. Materials of construction vary from carbon steel to stainless steel to accommodate corrosion resistance and various levels of contamination requirements. Common applications include super absorbent chemicals,...

Read More »

Roller Mill offers precise particle size reduction.

Multiple-stage, IMD 69.5 Gran-U-Lizer(TM) can integrate up to 5 grinder stages, resulting in high degree of single pass size reduction and narrow particle size distribution. Heavy construction provides minimal vibration and maintained tolerances under extreme conditions. Available with PLC control, integrated touch screen, controlled grinding atmospheres, and GMP qualification, system is suited...

Read More »

Ultra-Sanitary Mill is fully enclosed and dust-tight.

Featuring variable frequency controller and direct drive, stainless steel DefinerÃ-® measures 5 in. from inlet to outlet. Straight flow-through path eliminates hang up or accumulation in hoppers. De-agglomerating element with teeth and combs offers positive, once-thru anti-clog action. Fine milling element features high shear, rotor and screen which gently mills and conditions solids without...

Read More »

Lab Mill works in continuous and circulation modes.

Model DMQ-05 small media, Ã-½-liter tank-sized mill utilizes Delta discs, eliminating shaft whip and mill vibration. Discs are indexed to provide directed and uniform media distribution throughout mill chamber. Ring screens can be adjusted to accommodate use of grinding media from 1 mm to as small as .3 mm. Large open screen area positioned at end of mill facilitates cleaning. If required,...

Read More »

Precision Fabricating with Over 40 Years of Experience

Quality Sheet Metal specializes in delivering precision, value, and customer service. With a client base that spans many diverse industries and a reputation for excellence that goes back over four decades, our clients know that we can provide the optimal combination of value and flexibility regardless of the challenge. See our video to learn what we can do for you. Through investments in state-of-the-art design, manufacturing, and quality control systems, Quality Sheet Metal remains focused on maintaining a high standard of quality, customer service, and competitive pricing. With an emphasis on customer satisfaction, Quality Sheet Metal is dedicated to establishing long-term partnerships, similar to the ones they currently have with their valued clients. If you're looking for a new partner with extensive capabilities in sheet metal fabricating and finishing, look no further.

Read More »