Turning/Milling Center has 2-channel workshop programming.

Equipped with 12,000 rpm (18,000 rpm optional), 29.5 hp spindle, GMX 250 S linear Turning/Milling Center incorporates linear drive in Z-axis as well as cross-carriage slide with Y and B axes. Machine allows graphically-supported, 2-channel workshop programming on basis of adapted Plus IT controls from Heidenhain with integrated TurnPlus programming. Capable of 3D-workpiece simulation, modular VMC...

Read More »Turning Machines do not require reference point guiding.

Models CTX 310/410 are equipped with counter spindle expansion stage for 2-sided complete machining and Y-axis expansion stage for eccentric drilling and milling machining. Fast-indexing VDI servo turret (from 0.1 sec), also included, features 12 tool stations and optional driven tools. Both machines have 45Ã-

Read More »Vertical Machining Centers feature 3D controls.

Equipped with 8,000 rpm spindle (12,000 rpm optional), DMC 35 V Series features cast-iron bed with 3-point support in C-Frame design. DMC 635/835/1035 machines employ direct drive main spindle and 20x tool magazine with double gripper for 1.6 sec tool exchanges. Capable of rapid traverse speeds to 1,181.1 ipm, series uses roller guideways in all axes and CNC-controls with 15 in. TFT screen and...

Read More »

Machining Centers suit die/mold makers and parts producers.

Models 2216FX features rigid box-way construction, Steinmeyer ETA+ dual-mounted ball screws, and 8,000 rpm spindle speed. GE Fanuc Fadal 0i-MC Control provides over 200 advanced programming, operational, and troubleshooting features. Optional AI Contour Control adds look ahead capability to optimize acceleration and deceleration of cutting speed. X/Y/Z axes travel on 2216FX is 22 x 16 x 20 in.,...

Read More »Choosing the Right Cleanroom Equipment Supplier

This whitepaper discusses key considerations for choosing a cleanroom equipment supplier: what to look for, types of cleanrooms & their standards.

Read More »

VMC achieves roundness of 1.59 -µm in contouring.

Mid-size NV6000 DCG(TM) features DCG (Driven at the Center of Gravity) technology, whereby net driving force acts through center of axis for optimal surface finish and contouring accuracy. Machine provides X, Y, Z axis travels of 35.4, 23.6, and 17.7 in., respectively, with rapid traverse rate of 787.4 ipm for all axes. No. 40 taper spindle achieves max speed of 12,000 rpm, with 20,000 rpm...

Read More »

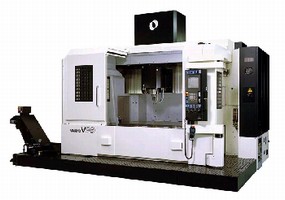

Vertical Machining Centers suit large mold manufacturing.

High-speed Models V99 and V99L help minimize benchwork and post-production polishing on large die and mold work. With 70.8 x 39.4 in. worktable, Model V99 features X, Y, Z axes of 59 x 39.4 x 31.5 in., while Model V99L provides X, Y, Z axes of 78.7 x 39.4 x 31.5 in. with 90.5 x 39.4 in. worktable. Machines offer rapid traverse and cutting feedrates of 787 ipm and come with #40 taper 20,000 rpm or...

Read More »Tong-Tai (Topper) Introduces a 20 Pallet Horizontal Machining Center - The HB500 at the IMTS-06 Show

VALLEY COTTAGE, NEW YORK (March 15, 2006): Tong-Tai (Topper) introduces a 20 pallet horizontal machining center - the HB500. This is the first of a series of horizontal machining centers the designs of which are based on proven concepts by well-established Japanese manufacturers. This design makes the machine suitable for general-purpose applications or high speed machining applications. The X &...

Read More »Tong-Tai (Topper) Introduces the TB-25-YMBC, its Latest 'Y' Axis Multi-Tasking Center at the IMTS-06 Show

VALLEY COTTAGE, NEW YORK (March 15, 2006): Tong-Tai (Topper) will introduce its latest 'Y' axis multi-tasking center at the IMTS-06 show. What distinguishes this against other 'Y' axis machines is the independent axis design. X, Y and Z-axis move independently and do not have the problems associated with axis on axis stacking. X, Y and Z-axis are 90 degrees to each other and do not require...

Read More »

Machining Centers work with large parts in compact area.

Suited for manufacturers working with larger high production parts, NXH3000 DCG(TM) HMC and NXV3000 DCG VMC have less than 30 ftÃ-² footprints and stand 9.8 ft tall. Both machines feature XYZ axis travels of 11.8 x 13.8 x 13.8 in. as well as 12.6 x 12.6 in. table that supports workpieces up to 440 lb. Uniform table height of 39.4 in. allows both machines to be combined in same production...

Read More »Mitsubishi Carbide Welcomes You to Visit us at IMTS 2006 in Booth E2126

Mitsubishi Materials USA Corporation, a world leader in carbide tooling extends a welcome to visit our booth E2126 at the McCormick Center in Chicago during the IMTS 2006 exposition September 6 through 13, 2006. We offer a complete range of metal cutting products for drilling, milling, turning and more. During IMTS, we will have daily product demonstrations in our booth featuring the most...

Read More »

Don't Let Your Money Drain Down the Hole...Drill Steel with Euroboor

As a globally recognized manufacturer of industrial grade portable tools, Euroboor is at the forefront of drilling and cutting technology. Our reputation as an industry leader is built on robust products that fit a wide range of industrial cutting and drilling applications. See our video to learn more about all of our quality products.

Read More »