CNC Machine targets automotive parts manufacturers.

Share:

Press Release Summary:

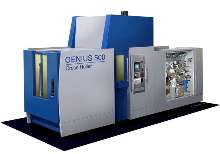

Single-spindle GENIUS 500 combines speed of linear motors along X and Y axes with force of ball screw along Z axis. It features XYZ travels of 630 x 630 x 1,000 mm, 500 x 500 mm pallet with 800 mm clearance diameter, and 16,000 rpm spindle with output of 25 hp/37.5 kW. Acceleration forces are resolved in vertical plane directly through walls of machine base, into machine foundations, enabling accelerations of 2.5 g and velocities up to 180 m/min.

Original Press Release:

Cross Hüller Announces: GENIUS High-Performance Single-Spindle CNC Production Modules

CNC Combines the Speed of Linear Motors Along XY Axes with the Force of Ball Screw Along Z Axis

STERLING HEIGHTS, MI - AUGUST 5, 2004 - Cross Hüller North America, a leading manufacturer of production systems for the global automotive and off-road/construction industries, today announced the GENIUS 500, a high-performance single-spindle CNC combining the speed and acceleration of linear motor drives with the improved stiffness and rigidity of a parallel kinematic construction for X and Y axis.

"The GENIUS 500 provides our customers with an extremely fast and easily adaptable machining system requiring a minimum of space," says Ron Quaile, general manager, Cross Hüller North America. "Automotive parts suppliers and other volume part manufacturers will improve quality, while reducing costs. That's the genius behind the GENIUS 500."

The GENIUS 500 features 630mm, 630mm and 1000mm X, Y and Z travels, a 500mm x 500mm pallet with 800mm clearance diameter and 16,000 RPM spindle with output of 25 HP / 37.5KW. Acceleration forces are resolved in a vertical plane directly through the walls of the machine base, into the machine foundations, enabling accelerations of 2.5g and velocities up to 180m/min. The Z-axis is powered by a conventional ball screw and servo motor combination to provide higher feed forces than possible with linear motor drives.

The GENIUS 500 is available with a pallet exchange system for stand-alone, small cell applications or with direct loading into a hydraulically actuated work-holding fixture via overhead gantry or robot.

About Cross Hüller North America

Cross Hüller North America is a business unit of Hüller Hille GmbH, a division of ThyssenKrupp Technologies. Cross Hüller provides low, medium ad high volume modular transfer line and agile production systems to the global automotive and off-road / construction industries. Cross Hüller provides a common global machine tool architecture, while offering local application engineering and support. Cross Hüller also provides extensive aftermarket services including spare parts, service, preventative maintenance and machine remanufacturing. Cross Hüller is ISO 9001 and ISO 14000 certified, and also QS9000-TE supplement compliant. For further information please contact us at: voice (586) 566-2400, fax (586) 532-3102, email sales@crosshuller.com. Or visit www.crosshueller.com.

About ThyssenKrupp MetalCutting

The ThyssenKrupp MetalCutting Group includes a strategic alliance of Cross Hüller, Hüller Hille, Giddings & Lewis, Hessapp, Fadal and Witzig & Frank for serving customers with global operations and regional markets. Customers include the automotive industry and its supplier operations, aviation and aerospace, medical engineering and the energy industry, mechanical engineering, tool manufacturing, mold making and job shops.