Collets and Guide Bushings suit Swiss-type lathes.

Headstock and sub-spindle collets are ground to precise size and TIR to meet precision machining requirements. Carbide-lined, Swiss guide bushings keep stock clean and unmarked, and extended-nose collets are suited for pick-off work or to compensate for tooling interference. Heat-treated to 40 Rockwell at head, they also serve as emergency collets.

Read More »

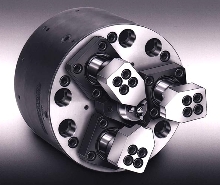

Milling Chuck clamps with high force and accuracy.

Ultra-Lock provides clamping torque 30 to 60% greater than conventional milling chucks and has run-out accuracy within 5 microns at 100 mm from chuck's nose. Compact nose ring reduces interference, and collets accommodate multiple tooling sizes. Chuck is available in 5 sizes to handle cutting tools from 1/8 to 2 1/2 in. Options include high-speed machining version and coolant delivery systems.

Read More »

Power Chuck has thru hole to swallow parts.

Pull-back, 3-jaw Series PUB provides accuracy for finishing applications. It has high gripping forces, component length control, and repeatability of 0.0004 in. All sliding surfaces are hardened and ground. Enlarged thru hole makes it suitable for shaft work pieces, including gear shafts and axle shafts. Thru-hole diameters for PUB206, PLUB208, and PUB210 are 39, 50, and 72 mm, respectively.

Read More »

Collets expand spindle applications.

Collet models 1C and 3C for Spindle Headstock Assemblies can be used as original equipment in lathes, grinding machines, and special purpose machines, including the manufacture of medical and electronic components. Accepting collets directly into spindle without use of additional collet fixtures, capacities range from 1/64 to 1-3/4 in. for OD holding, 3/4 to 6 in. for step chuck OD holding, and...

Read More »

The Benefits of Polymer Coatings in Tribology

This white paper provides an in-depth review of how polymer coatings are beneficial in tribology.

Read More »

Retractable Jaw Chuck comes in 8, 10, and 12 in. sizes.

Retractable Jaw Chuck features jaws that extend and retract to enable turning of shaft in single operation. Heavy cuts can be made without slippage by extending jaws to clamp shaft during roughing operations. Self-contained facedriver changes out for different sized shafts. Driver pins mechanically compensate for out-of-square parts, while spring-loaded center compensates for center size...

Read More »

Milling Chucks offer heavy clamping.

Power Milling Chucks withstand up to 200 lb-ft of tightening force without damaging mechanism. Internal diameter collapse capability allows use of tools that are not H6 tolerance. Chucks provide concentricity with collet like 360Ã-

Read More »

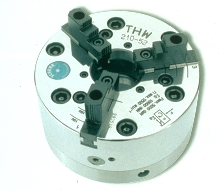

Lathe Chuck provides performance and accuracy.

THW Quick Jaw Change Series features wedge-bar serration mechanism. It provides less than one-minute jaw change, repeatability to .0006 in. TIR, and gripping forces capable of 6,000 rpm. Large Bore Power chuck line, designed to meet oil field market requirements, offers thru-hole bores to 22 in. Each Power Lathe Chuck is case hardened and ground.

Read More »

Automatic Chuck is air operated.

SquareOne AutoChuck bolts directly to most modern machines with C-axis. It has industry standard bolt pattern, porting for air blow off, holder sensing, and central flushing. Chuck provides accurate positioning and repeatability of holders, 90 deg indexing of all holders, and ability to maintain perfect concentricity when changing from large to small holders.

Read More »

Replacement Chucks fit Goss & DeLeeuw machines.

G-123-9, G-123-9.3, and G-123-12 direct replacement chucks are available for 3 models of Goss & DeLeeuw 123 Rotary Transfer Machine, while G 6x6, G 8x8 and G 11xl0 chucks are available for Model 4 Spindle Chucking Machine. Chucks are manufactured from high-alloy steel with all wearing surfaces hardened and ground.

Read More »

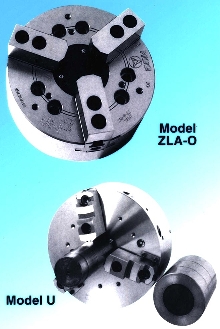

Power Chucks provide additional stroke travel.

Model ZLA-O and Model U solid center power chucks accept standard top jaws and feature hardened and ground keyways. Model ZLA-O is available in 3-jaw and 2-jaw configurations, operates up to 3000 rpm, and provides up to .92 in. jaw travel. Model U hydraulic actuated gear chuck grips different size workpieces without any change of top tooling. It delivers up to 4 in. jaw travel, and operates up to...

Read More »

Precision Machining Solutions with Over 25 Years of Experience

Quality, customer service, and unbeatable value are the hallmarks of Hogge Precision. Since 1989 we have built a reputation as the go-to precision machining source, servicing many demanding industries. For CNC machining and screw machining, there are few manufacturers that can match our capabilities and expertise. See our video to learn more.

Read More »