Hydraulic Power Chuck operates at 7,000 rpm.

Featuring 66 mm thru hole, 8 in., 3-jaw Model GHA6-8-66 allows users to chuck large parts or bar feed large diameter bar. Clamping repeatability is less than 10 microns. Chuck permits machining at speeds and feeds required for cutting aluminum, and is suited for machining steel, especially in hard turning applications.

Read More »

Wheel Chuck suits premachining operations.

Series WDF Deflash/Degate Wheel Chuck removes flash and gating out of cast aluminum wheels when run on automated wheel lathe. Chucking diameters range from 15-24 in., and various wheel sizes can be handled by single chuck. Part quality is optimized by consistent heat treat operations and by eliminating flashing that can cause problems in painted wheels.

Read More »Milling Chucks offer magnetic workholding.

Featuring electronically-activated permanent holding, Turbo-Mill(TM) MMC chucks can be disconnected from power supply for portability. They allow single set-up machining with 5-sided accessibility, and produce uniform holding over entire workpiece surface. Drilled and tapped holes in magnetic face facilitate positioning of riser blocks. Sizes range from 13.62 x 11.88 x 3.14 in. to 40.07 x 19.76 x...

Read More »

Collet Chuck suits lathes with programmable barloaders.

ProdyneÃ-® Servo Collet Chuck utilizes pull-to-close design that maintains position of barstock against barloader pusher as chuck closes, eliminating need for turret stop for positioning. Models S16, S20, S22, and S26 offer max bar capacity of 1.625, 2.000, 2.225, 2.625 in., respectively. Wedge design provides high grip force regardless of rpm. Features include concentricity adjustment...

Read More »

Quality Assurance and Reliability in Everything We Do

Learn about SSP quality assurance metrics, certifications, warranty, and safety and delivery guarantees in our free eBook.

Read More »

Collet System operates up to 40,000 rpm.

Available in 30, 40, and 50 tapers, VC Toolholder features slim, smooth profile that eliminates noise related to high-speed rotation. Dampening of micro harmonic vibrations is achieved with use of groove under nut. Eight degree collet design contributes to rigidity and gripping torque, while extended straight portion of collet pilots and maintains concentric placement of tool. Flat shoulder...

Read More »

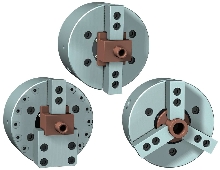

Specialty Chucks are designed for odd shaped workpieces.

Long-stroke ML Series power chucks are available in triple-, dual-, and single-jaw configurations. ML 3-jaw configuration features up to 1 in. stroke per jaw and is suited for gripping workpieces with flanges that must be swallowed. MLT 2-jaw chuck is suited for square, rectangular, or unusually shaped workpieces, while single-jaw MLV incorporates custom-designed fixed locator or jig for locating...

Read More »

Power Chuck has near zero z-axis repeatability.

Available in 6 and 8 in. sizes, DL Series dual lock, radial guideway chuck features no jaw lifting. Product actuates and clamps workpiece using radial actuation, then, as chuck develops gripping force, performs final axial, z-axis pull-back movement to fixed stop. This ensures accurate length control and axial repeatability. Sealed to keep out dust particles and retain lubrication, chuck allows...

Read More »Pneumatic Chuck suits machines without hydraulic systems.

Model MK5 Self-Contained Pneumatic Power Chuck has increased rpm rating and larger thru-holes. Push-button control is located on top of distributor ring on chuck, for easy operator access. Foot pedal control is optional. Chuck eliminates need for hydraulic pump, tank and control unit, hydraulic actuator, or custom made drawtube and hydraulic actuator mounting adapter.

Read More »

Collet Chucks suit main and subspindle applications.

Accu-Length CNC Collet Chucks have runout guarantee of 0.0003 in. TIR or better. Collet is fixed within chuck bore and tapered sleeve pushes forward over collet to compress it, resulting in precise Z-axis positioning of workpiece. Chucks include custom-machined drawtube connector for installation. They are available for 5C, 16C, 3J, S-20, S-26, S-30, S-35, and S-40 collet styles.

Read More »

Pneumatic Mechanical Chucks ensure precise concentricity.

Available in 3-12 in. dia, chucks expand pneumatically for positive, instant lock up and release. Suited for all shaftless unwinds and rewinds, products incorporate steel body and expandors, and are available with flange or cantilevered type mountings. When running different core diameters, interchangeable adapters are available that can be fitted onto one base chuck.

Read More »

Increase Workplace Safety, Manage Heavy Loads with Equipment from A-Plus Warehouse

A-Plus Warehouse carries a wide selection of commercial and industrial material handling equipment at affordable prices. Check out the video to learn more.

Read More »