Multi-Axis Machining Center has highest accuracy available.

Model HU50-5AX Trunnion Table 5-axis CNC machining center holds 0.00012 in. true position (ISO 230-2) through all linear axes and 0.001Ã-

Read More »

HMC is offered with multiple pallet storage systems.

Horizontal Machining Center (HMC) 170 is available with multiple pallet storage system, which includes setup station, six queue locations, and machine pallet. Load station rotates 360Ã-

Read More »

Machining Center performs uninterrupted operation.

Performance Series 30 taper TC-R2A performs non-stop drilling, tapping, and milling operations via its quick table and traveling column. Quick table allows for simultaneous workpiece loading/set up and operation, accommodates housing for notebook-sized personal computers, and turns 180Ã-

Read More »

Machining Center provides rapid production.

Model TC-S2A drills, taps, and mills workpieces with drum-style tool changer (14-tool capacity) and spindle speeds up to 16,000 rpm. Traverse rates for X/Y axes and Z-axis are 1,417 and 1,968 ipm respectively. Able to be used with G-code and proprietary non-stop tool change code, controller offers conversational system that reduces time from programming to machining.

Read More »

Why You Need a Dehumidification System in Your Residential Swimming Pool Room

Learn about the role of dehumidifiers in indoor pool applications.

Read More »

Grinding Center offers modular design and digital control.

MGC-Special is equipped with precision hydrostatic rotary NC table, with brushless ring torque-motor drive and Heidenhain direct measuring scales, allowing index accuracy of Ã-

Read More »

End Facing and Centering Machines work both ends simultaneously.

Model MC 650 has 2 horizontally opposed #50, 20 hp taper spindles, each with 3-axis CNC plus 20-position automatic tool changer. Work capacity is 8 in. dia. x 59 in. long, suitable for machining solid shafts, with or without flanges, bars, and tubular-type parts. Model CM 132/IS040/TC12 has 2 horizontally opposed #40 taper spindles, each with 2-axis CNC and 12-position tool changer, for work...

Read More »

Horizontal Machining Center handles large payloads.

Model a71 horizontal machining center, with 20 in. pallet and standard 50-taper, 10,000 rpm spindle, is designed for medium- to high-volume production. It offers ring-type, 60-tool magazine, with 6-12 sec seek times, complemented by automatic tool changer with 1.7 sec tool-to-tool and 3.2 sec chip-to-chip times. System includes next generation Geometric Intelligence (GI) servo control and handles...

Read More »

Vertical Machining Center has 0.9 second tool change time.

Variaxis 630 offers rotary table with tilting angle of 150Ã-

Read More »

Machining Center integrates multiple processes in one setup.

Variaxis 500 offers rotary table with A-axis tilting angle from -120Ã-

Read More »

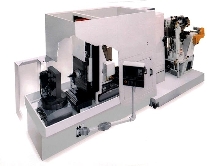

Machining System allows choice of spindles and no. of axes.

PB Plus(TM) modular precision machining system utilizes modular construction, which allows units to be implemented in stages. Each system is built around one or more standard modules, which consists of base with feed slide; enclosure; hydraulic, lube and electrical systems; CNC control; and chip removal system. Basic module has linear displacement accuracy of Ã-

Read More »

Basalt America Announces Stronger, Lighter, and Corrosion-Free FRP's (Fiber Reinforced Polymers)

Fiber Reinforced Polymers (FRP), represents a truly groundbreaking advancement in structural reinforcement. Lightweight, strong, and green, they are changing the way the construction industry thinks about rebar. Unlike steel, FRPs don't rust and are far stronger than standard rebar. To learn why Fiber Reinforced Polymers are poised to change the way the world builds, see our video.

Read More »