Machining System allows choice of spindles and no. of axes.

Share:

Press Release Summary:

PB Plus(TM) modular precision machining system utilizes modular construction, which allows units to be implemented in stages. Each system is built around one or more standard modules, which consists of base with feed slide; enclosure; hydraulic, lube and electrical systems; CNC control; and chip removal system. Basic module has linear displacement accuracy of ±0.00012 in., and can be equipped with six axes (max) with travel rates to 600 ipm.

Original Press Release:

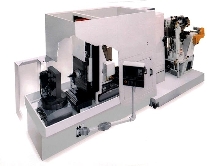

New EX-CELL-O PB Plus(TM) Modular Precision Machining System Combines Flexibility and Precision

Sterling Heights, Mich., May 14, 2002 - EX-CELL-O Machine Tools Inc., an IWKA Company, has introduced a new family of modular machines to address manufacturers' requirements for flexibility, re-configurability and precision for a variety of production metalcutting applications. Called the "PB Plus(TM)", this new modular precision machining system is configured from standard building blocks that permit users to select exactly the number of axes needed for the application, as well as a wide choice of spindles and options. The new machine range is adapted from EX-CELL-O's legendary "PB" series of precision boring systems which are recognized industry-wide as the standard solution for critical machining applications.

EX-CELL-O engineers say that the new PB Plus system provides the flexibility of a machining center and the precision of an EX-CELL-O boring machine in a form that can be customized and even upgraded to satisfy changes in applications. Its modular construction allows for PB Plus units to be implemented in stages as production volumes increase. In addition to stand-alone applications, additional modules can be added to form a two- or three-way machine, or standard multi-axis modules can be arranged in cells or even as a small transfer machine.

Each PB Plus system is built around one or more standard modules which consists of a base with feed slide, enclosure, hydraulic, lube and electrical systems, CNC control, and chip removal system. The basic module has linear displacement accuracy of +/-0.003 mm (+/-0.00012"). Each base module can be equipped with up to six axes of controlled motion.

Users can select from cross slides, vertical slides and rotary tables to obtain the necessary axis motions for the particular application. Other options include tool changers and head indexers, as well as a choice of single spindle and multi-spindle heads. Optional servo spindle and servo drawbar are available to handle tool compensation and feedout heads.

The new PB Plus modular precision machining system features absolute encoders and scales in place of limit switches. An open architecture, PC operator interface is provided. Self-contained hydraulic power and lubrication units are provided, along with comprehensive diagnostics. The machine features a dry-floor guarding design with a self-contained coolant/chip handling system. The rigid cast iron base has two-point pick-up and requires no special foundation.

Axis travels for the PB Plus are: Z-axis (main slide) 600 mm (23.6"); X-axis (cross slide) and Y-axis (vertical slide) 440 mm (17.3") each. Maximum rapid travel rate for all three main axes is 15.25 m/min (600 in/min).

Complete specifications and information on the new PB Plus modular precision machining system can be obtained by contacting EX-CELL-O Machine Tools Inc., 6015 Center Drive, Sterling Heights, Ml 48312-2667; phone (586) 939-1330; ex-cell-o.com.

EX-CELL-O designs and builds machine tools, manufacturing systems, and testing machines for both high- and low-volume production of complex, high-precision parts and assemblies. EX-CELL-O machine tools and manufacturing systems are recognized as technology and productivity leaders in the global automotive and aerospace industries. EX-CELL-O is part of EX-CELL-O Holding AG, Eislingen, Germany, which is a division of the IWKA group of companies, Karlsruhe, Germany. Together, the IWKA companies provide a comprehensive range of manufacturing and production technology solutions.