Horizontal Machining Centers combine machining and turning.

Multi-tasking H5 GEMINEX machining centers accommodate parts 50 in. in diameter and larger. Linear motor rotary table comes in 300 rpm high-torque or 700 rpm high speed models. Featuring full 180Ã-

Read More »

Horizontal Machining Center has pallet change time of 7 sec.

Utilizing out-of-cut technology to reduce part cycle times, model a61 has X-, Y-, and Z-axis travel of 28.7 x 25.6 x 28.7 in. and work zone of 32 x 36 in. Pallet size is 19.7 in., max load capacity is rated at 1,540 lbs, and rapid traverse and feedrate are 1,970 ipm. Using Geometric Intelligence servo control with Radical Mode, unit comes equipped with tool monitoring capabilities; 40-taper,...

Read More »

Machining Center uses thermal displacement compensation.

Table of M-V50-FM vertical machining center moves in Y-axis only, to minimize required floor space. Headstock construction and ballscrew with 50 mm dia and 12 mm lead increases machine's rigidity. Travels are X-31.5, Y-20.1, and Z-17.7 in., with 15-position ATC. Features include low vibration 30 hp integral spindle, and spindle speed of 14,000 rpm, with 30,000 rpm option.

Read More »

Manufacturing Cell cuts aluminum, cast iron, and steel.

Module-Mation(TM) 3-Axis Manufacturing Cell uses reconfigurable elements including spindle, column position, way style, and compound X-Z or Z-Y. Module parameters include 500 mm Z-axis, 400 mm X-axis, and 400 mm Y-axis. Traverse rate is 950 ipm, acceleration rate is 80 in./secÃ-², and thrust is 3,000 psi. Module accepts 40 or 50 Milling Taper or HSK 63 tooling. Motorized spindle, belt-driven...

Read More »

Super Precision Bearings for Machine Tools: Factors For A Successful Spindle Bearing Set Up

This white paper provides an in-depth overview into choosing the right bearing for machine tools.

Read More »

Vertical Machining Center uses linear motor technology.

Model VL 50 offers speed and motion control necessary to perform high-speed point milling in multi-axis contouring applications. Linear technology provides geometric and positioning accuracies, while low-heat, counteracting, permanent magnet linear motors eliminate mechanical backlash, vibration, and noise. Product has X, Y, Z work envelope of 16 x 12 x 8 in. and offers traverse and cutting feed...

Read More »

Machining Center offers full spindle power from 315-6,000 rpm

Model VM560 features 20/25 hp geared head spindle that delivers 6,000 rpm with 415 lb-ft torque. It includes 1,000 psi spindle thru coolant system, and totally enclosed splash guard. All axes have 3 gibs for long life and easy maintenance. CAT 50/30 tool magazine offers 2.0 sec high speed ATC. Fanuc 18MB control features 160M memory, custom macro B with 600 variables, tool life management, and...

Read More »

Machining Center offers automatic attachment-changing option.

Bridge-type, 5-axis Series MP-5F Die and Mold Machining Center provides universal workpiece machining using combination of swiveling head and motor spindle with switchable planetary gearing. Swiveling action makes 2 axes possible using A- and C-axis or B- and C-axis milling heads. Axes can alternatively be used as NC axes, making rough milling and high-speed cutting possible in one setting. Three...

Read More »

Machining Center offers max spindle speed of 12,000 rpm.

Vertical Center (VC) Nexus 510C features high-speed rapid traverse rate of 1417 ipm at 0.5 G acceleration and 2.9 sec chip-to-chip time. Spindle is driven by 25 hp motor. Machining area provides X-axis travel of 41.3 in., Y-axis range of 20 in., and Z-axis travel of 20 in. Table size is 51.18 x 21.65 in. with load capacity of 2640 lb. Tool magazine stores up to 30 tools of 40 taper. Tool-to-tool...

Read More »

HMC provides small to medium production batch machining.

Model MCH 250 offers working range of 800 x 800 x 800 mm. It includes 43 kw spindle drive, capable of 45-6,000 rpm and 955 Nm torque. Machine moves at 50,000 mm/s rapid traverse with 4 m/secÃ-² acceleration. Pallets are changed within 12 sec, permitting simultaneous part loading and machining. Rotary indexing table includes pin-type pallet alignment for 0.1 mm repeatability. Tool changer...

Read More »

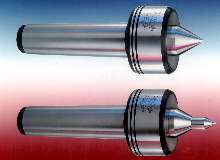

Live Centers suit manual and CNC turning applications.

Tough Little Centers (TLC) are offered in standard and extended-point models with shank sizes from 2MT-6MT. Short, thick point and oversized, double-row, angular-contact bearing provides rigidity. Needle roller bearing located within shank dampens vibration and reduces point deflection. Steel shield and neoprene seal protects bearing assembly from coolant and chips. Body and point are hardened...

Read More »

Basalt America Announces Stronger, Lighter, and Corrosion-Free FRP's (Fiber Reinforced Polymers)

Fiber Reinforced Polymers (FRP), represents a truly groundbreaking advancement in structural reinforcement. Lightweight, strong, and green, they are changing the way the construction industry thinks about rebar. Unlike steel, FRPs don't rust and are far stronger than standard rebar. To learn why Fiber Reinforced Polymers are poised to change the way the world builds, see our video.

Read More »