Multiple Profile System changes tools in 0.5 seconds.

MPS 08 Multiple Profile System allows users to machine semi-finished stock up to 10 meters long. It accepts semi-finished round bars, square bars, tubes, angle profiles, or bent profile materials. Two synchronized NC fixtures can rotate workpieces at up to 50 rpm. Installation area is less than 20 sq ft, and MPS 08 may be adapted to standard machining centers. Chip-to-chip times are clocked at...

Read More »

Multi-Tasking Machine combines machining and turning centers.

Integrex e-410H offers milling spindle with B-axis, C-axis and X, Y and Z-axes. 35 HP main and second spindles, with full C-axis, operate at up to 4,000 RPM and deliver 470 ft-lb of torque. B-axis has 240 deg travel range and performs full 5-axis contouring. E-mail communication through cell-phone link offers instant notification of machine alarm or production status. Fusion 640M Pro CNC system...

Read More »

Horizontal Machining Center produces near-dry chips.

HORKOS HFN-R40H machining center, with Minimum Quantity Lubrication (MQL), consumes just 20 to 50 mL per hour and minimizes concerns associated with cutting fluids when drilling, reaming, boring or tapping. It has 40-taper spindle and 20.8 x 22.0 x 20.8 in. work area travel. Rigid z-axis ram carries 5.5, 7.5, or 15 kW, 12,000 or 15,000 rpm direct-drive spindle. Machine has automatic tool changer...

Read More »

Horizontal Machining Centers are FMS system-ready.

HU50-5AX tilting trunnion table type machine accommodates part dia up to 27 in. and weights up to 1430 lbs. 50 taper spindles are available with up to 12,000, or 15,000 rpm and 40 taper up to 20,000 rpm. HU40T features max part dia of 20 in. 40 taper spindles are available with up to 12,000, 15,000, 20,000 rpm or 30 taper up to 40,000 rpm. Both machines hold 0.00012 in. true position through all...

Read More »

How to Choose the Right Label for Your Application

This ebook discusses factors to consider when choosing the optimal label for your application.

Read More »

Machining Center is based on indexing dial design.

Turn 6 LC(TM) flexible dial machine performs single-clamp, multiple-process operations. It combines up to 6 servo-controlled CNC motorized chucking spindles mounted on Hirth Coupling main indexing rotary transfer table. Each station handles 8 in. work envelope. Flexible CNC control allows for single-point machining using turning tools and G-programming logic. Center offers true C-axis...

Read More »

Horizontal Machining Centers allow user to choose travels.

Modular HS-4, HS-6 and HS-7 are available in sizes from 84 x 50 x 60 in. up to 150 x 66 x 60 in. Each machine comes equipped with 50-taper spindle, 30-hp vector drive and 38-tool side-mount tool changer to handle heavy-duty cutting and metal removal. All are available with built-in fourth-axis rotary table.

Read More »

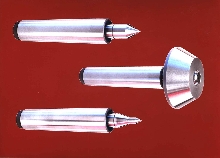

Live Center compensates for thermal expansion.

Spring-Type Live Center prevents damage to workpiece by sliding along z-axis. As heat from machining process causes workpiece to grow, rotating point is pushed back into body of center. Bearing, positioned between point and series of stacked disk springs, maintains thrust capacity. Low-profile body provides tool clearance and 0.0001 in. accuracy. Four point styles suit most applications.

Read More »

Vertical Machining Center offers high intensity lighting.

Arrow Series 2 VMC-1250C features Ultimate Performance(TM) and Profibus I/O interface technology. Its digital vector spindle drive provides 30 Hp Max, 25 Hp MTDR. Spindle acceleration allows 40 series spindle to reach 8,000 rpm in 1.8 seconds, and drive system provides constant torque regardless of load. Process matching feedrates of 590 ipm are combined with rapid traverse rates up to 1,416 ipm....

Read More »

Micro Air's Dust, Fume, Mist Collection Equipment Facilitate a Safe Work Environment

Dust, fume, and mist collectors from Micro Air promote a safer, more productive work environment. Our wide array of products are available to the industrial manufacturing sector for processes such as welding, cutting, grinding, blasting, and more. Check out our video to learn more.

Read More »