Walter Valenite

Waukesha, MI 53188

Share:

Coolant is formulated for general purpose machining.

ValCOOLÃ-® VNT-755 consists of natural and synthetic emulsifiers plus chlorinated extreme pressure lubricant that promotes cooling properties while resisting chip weldment to cutting edge. Coolant also contains biostable microbial package that controls rancidity and protects against bacteria and mold. Rated for moderate to heavy-duty operations, VNT-755 is suited for cutting operations such...

Read More »

Inserts machine gummy, non-ferrous, and steel materials.

ValTURN(TM) Turning System tools include 3 top form geometries: M8, R4, and C2. Double-sided inserts of ANSI Negative type geometry come in various shapes and thickness, offering 98 specific performance options. Used in continuous and interrupted cuts, M8 suits medium machining applications. Heavy-duty R4 is designed for roughing of steels and cast irons, while positive cutting land on C2 ensures...

Read More »

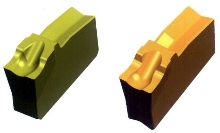

Grooving/Parting Inserts have one-edge design.

Available in various cutting directions, ValGROOVE(TM) Grooving and Parting Tool System includes inserts offered in 2 chipbreaker geometries and 4 grades. VSG-FG inserts have general-purpose geometry that minimizes vibration in grooving and parting operations. Also available, VSG-CG inserts utilize combination of cutting geometry, corner radius, and lead angle for parting applications. They are...

Read More »

Milling Cutters machine high-temperature alloys.

Available in face and end-mill configurations, ValMILL(TM) V590 provides square, 90Ã-

Read More »

Tooling System facilitates hard part turning.

Machining steels and alloys hardened to 45-62 Rc levels, ValEDGE Hard Part Turning System utilizes ceramic and CBN inserts as well as ValTURN(TM) ProGRIP(TM) toolholders. It is provided with T-Land corner break width and angle as well as light hone finish. For vibration-free machining, spring-loaded clamp grips insert in 2 places. Inserts, offered with 35, 55, 60, 80, and 90Ã-

Read More »

Pentagonal Face Mills work with variety of materials.

ValMILL(TM) V555 Series inserts feature pentagonal shape with 5 cutting edges. Available in 6 cutter body diameters from 2-6 inches, products require 4-9 inserts each. Recommended max rpm ranges from 19,000-9,000, and depth of cut is 0.200 in. Suited for roughing, semi-finishing, and finish face or surface milling applications, face mills deliver consistent dimensional and surface qualities to...

Read More »

Extended Flute End Mills are suited for slab milling.

ValMILL(TM) V595 end mills employ cutter body design and geometry that deliver smooth cutting action for consistent dimensional and surface finish results. Products are available in 8 models that use AP10 or AP13 inserts and Weldon or cylindrical shank configurations. Cutting diameters range from 1.000-2.000 in., depending on model. Available coatings include multi-layer PVD TiAlN/TiN and...

Read More »

Hard Part Tooling System has insert and tooling options.

Capable of machining steels and alloys hardened to 45-62 Rc levels, ValEDGE(TM) utilizes proprietary ceramic and CBN inserts plus ValTURN(TM) ProGRIP(TM) family of toolholders. System takes advantage of stabilized microstructures and mechanical properties of materials while eliminating or reducing time consuming secondary finishing operations. It also provides tolerance and surface finish control...

Read More »

End Mills provide plunge milling, drilling, and channeling.

ValMILL(TM) V520 drill/end mills are available in 0.826, 1.023, and 1.299 in. diameters with shank diameters of 0.750, 1.000, and 1.250 in., respectively. Units feature 2 identical trapezoidal inserts located in same axial plane, allowing 2 cutting edges for plunging and end milling operations. Inserts have PVD-coated, micrograin grade and top-face geometry for resistance to wear and thermal...

Read More »

Mills suit roughing, semi-finishing, and finish machining.

ValMILL(TM) V490 Series square-shoulder face mills have 90Ã-

Read More »