Quick Change Pallet System promotes flexible operation.

With 0.005 mm repeatability, UNILOCK provides accurate set-ups of workholding fixtures for production run machining and grinding operations. Through its clamping system, workpieces can be set and moved through multiple machining operations with minimal resetting. Product consists of stationary modules, installed individually or in multiples, directly on machine's worktable or tombstone. Existing...

Read More »

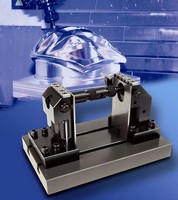

Clamping System is designed for 5-axis machining centers.

Providing up to 40 kN clamping force, Model VB 5 AX 100 allows high speed, continuous 5-axis cutting motion of sculptured surfaces, pockets, and other 3D features in single clamping setup. System eliminates jaw deflection and/or part misalignment during machining operations. Features include clamping width of 2-236 mm, clamping depth of 8 mm, and height above machine table of 175 mm with extended...

Read More »

DE-STA-CO to Showcase New, Patented Selection of Automation and Workholding Solutions at ATExpo

Madison Heights, Michigan, July 17, 2006 - DE-STA-CO will feature its entire line of products ranging from manual clamps to automation solutions at this year's Assembly Technology Expo (ATExpo) in booth #611. ATExpo will be held at the Donald E. Stephens Convention Center in Chicago, Illinois from September 26 - 28. The newest product to join DE-STA-CO Robohand's impressive list of automation...

Read More »

Fixture Clamp provides positive down force.

Available in 5 sizes and several styles, Pitbull Clamp features low gripping profile and generates vertical and horizontal clamping forces. It uses standard cap screw and oil-resistant O-ring. Clamp includes tool steel knife edge for aggressive stock removal and tool steel blunt edge for general purpose use. Brass version is available to help prevent marring of workpiece.

Read More »

An Introduction to Plastic Injection Molding

We developed this eBook with designers, engineers and purchasing specialists in mind. It is written to provide a basic understanding of plastic injection molding presses, processes and costs. Our goal is to make our customers more knowledgeable about what goes into making a plastic part.

Read More »

Workholding Blocks enable machining of 5 sides.

Using permanent, rare earth magnets, MagVISE Blocks securely hold workpieces without manual fixturing or vise set-ups. Each is rated to 4,620 lb of holding power, with 3.5X safety factor, for over 16,000 lb of magnetic force. Blocks use no electricity, are maintenance-free, and will never wear out. They can be ganged together to create custom workholding solutions.

Read More »Welding Clamp is rated 500 A at 60% duty cycle.

Designed to solve problem of inadequate grounding of weld arc, Ground Hog prevents current restriction by combining large copper contact point with clamping pressure, facilitating transfer of electrical current in full circuit. To further ensure complete arc, Ground Hog controls electrical current by isolating contact surface and transfer to cable connection. Clamping force is 465 lb using Strong...

Read More »Workholding System utilizes electro-permanent magnets.

Available with pole sizes of 50, 75, and 100 mm, MAGNOS Magnetic workholding delivers uniform clamping force due to poles' square geometry. Additional pole extensions are available as accessories to improve workpiece location and compensate for surface irregularities. Pole extensions act as workpiece support, aiding in precise positioning of different workpieces. Use of magnets enables 5-sided...

Read More »New Kurt HDL ClusterTowers(TM)

Provide Eight Clamping Stations With Large 4 Inch Openings For High Density Clamping - They Have Machinable Quick Change Jaws For Flexible And Fast Setups Minneapolis, Minnesota: Kurt advances the workholding market again with its new generation HDL ClusterTowers(TM). Providing repeatable clamping to 0.001 inch, these towers hold multiple parts in eight clamping stations for maximizing machine...

Read More »Clamping System offers high-density workholding solution.

MultiChuck MMY Concentric Clamping System provides manual self-centering static workholding solution for machining centers, milling machines, and grinders. Top face operation optimizes number of chucks that can be banked closely together. Available with 2 or 3 jaws, system can be provided as standard in chuck sizes of 80, 100, 125, and 150 mm. It combines fast initial jaw travel with controlled...

Read More »Motorized Work Holder delivers fully adjustable operation.

Suited for positioning and rotating small parts in micro-welding and similar applications, bench-top Micro-Star features smooth, slow rotation that ranges from 1-12 rpm every 8 min. Its 3 in. dia, 3-jaw chuck, with 6 in. dia faceplate, is suited for mounting small parts. Able to tilt from horizontal to vertical in 15Ã-

Read More »

Eliminate Expensive Repairs with the Hot-Shot Pipe Thawing Machine

The new Hot Shot Pipe Thawing Machine delivers an innovative and highly effective approach to thawing frozen pipes. Easy to use and versatile, it is loaded with robust features that further suit it to many challenging environments. To learn all about it, see our video.

Read More »