Pendulum Holder positions workpieces quickly.

EROWA 3D-pendulum holder enables attachment of workpieces on outside or directly on WEDM center in desired horizontal machining position. Holder features eccentric adjustment facilities in 3 axes which allow workpiece to be aligned in proper position quickly and easily. Pendulum holder can be used for workpieces up to 15 kg, has repeatability of 0.002 mm, and can be used with automatic handling...

Read More »Clamping System solves workholding challenges.

StrongHold(TM) components work as part of complete system and include Swing/Pull clamps with holding capacities up to 4500 lb. Clamps come in threaded and block body, with cartridge and manifold mount. Single-acting and double-acting versions are available. Line also offers Retracting Clamps, Edge Clamps, Thru-Hole Hydraulic Rams, and Collet Chucks. Two hydraulic pump types (electric and air...

Read More »

Workholding Systems suit HMC and VMC applications.

System 5 is offered in 6 sizes ranging from 2 to 6 in. VMC systems are available in either high strength aluminum (Qwik-Lok) or cast iron (BiLok). HMC systems (Multi-Lok) are offered in configurations consisting of 4-sides up to 8-sides, double stacked. Each system includes corrosion resistant, stainless steel slide assembly and high strength aluminum snap on/off machinable jaws that are...

Read More »Cartridge provides power-off clamping force.

Amforce(TM) Force Cartidge applies constant clamping force in applications for fixtures, tools, and pallets to hold parts and components when pressure lines are disconnected. Heavy-duty disk springs are used to produce high pull force on clamp arms. Hydraulic pressure is used only to unclamp work piece; therefore, hydraulic failure has no effect on workholding capability. Cartridge is offered in...

Read More »

You're Gonna Need a Bigger Boot

Learn about sealing boot types and applications in marine environments.

Read More »

Workholding Vise suits small machining centers.

CarvLock(TM) HDM6 2-station vise has overall length of 13.750 in. and is designed on 80,000 psi iron base. It produces approximately 11,000 lbs of clamping force at 100 lbs of torque with repeatable clamping to .001 in. Vise is available in 2-station pallet, 4-station tombstone (back-to-back), and 8-station towers, and in manual and hydraulic models for use on vertical and horizontal machining...

Read More »

Workholding Systems have modular clamping components.

SeraLock(TM) 8 and 12 clamping station Tower and multiple station Pallet systems have precision serrated surfaces that match and align with serrated moveable jaw modules. No special equipment or skill is required to align clamping components. Accessories include Magnetic Workstop for positioning of parts; Koolant Shield that keeps coolant within confined area of vise to avoid coolant waste; and...

Read More »

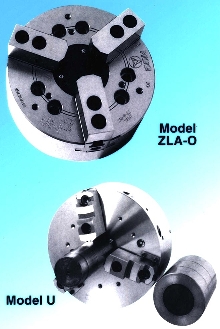

Power Chucks provide additional stroke travel.

Model ZLA-O and Model U solid center power chucks accept standard top jaws and feature hardened and ground keyways. Model ZLA-O is available in 3-jaw and 2-jaw configurations, operates up to 3000 rpm, and provides up to .92 in. jaw travel. Model U hydraulic actuated gear chuck grips different size workpieces without any change of top tooling. It delivers up to 4 in. jaw travel, and operates up to...

Read More »

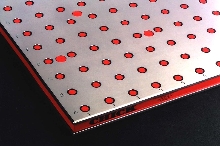

Workholding System works with VMCs.

Made of precision ground cast iron, Foundation workholding system is customized for each vertical machining center. It incorporates alpha-numeric labeling system to simplify building and cataloging of fixtures. Each hole within 50 mm grid pattern has 12 mm bushing for accurate location and M12 thread for bolt down. Holes are sealed with chip plugs preventing build up of chips.

Read More »

Vises, Indexers, and 90 Deg Heads offer many configurations.

Bock Workholding Systems Twin Vises consists of 4, 8, 12, and 16 station MonoQuads. Twin Vises offers up to 8 in. jaw travel and quick change, reversible, fully machinable soft jaws. Hard-coated aluminum Bock Locator Plates with alpha numeric coded holes for baseline reference achieve +/-.001 in. repeat setups. Tsudakoma Indexers offer compact AC servo motors and full 4th axis interfaces. Right...

Read More »

Machining Towers align parts accurately.

SeraLock(TM) Towers have 8 or more clamping stations with serrated mounting surfaces, suitable for small and mid-size horizontal and vertical machining centers. Serrations on mating surfaces are machined so that exact match is created between surfaces, and no special equipment or skill is required to align clamping components. Spacing or pitch of serrations allows use of variety of short stroke...

Read More »

SpillVak Absorbs Up to 6X More Fluid Than Rock- and Clay-based Absorbents

Are you struggling to find an absorbent that doesn't result in at least some leaching? SpillVak outperforms all rock and clay-based materials. Check out our video to learn more.

Read More »