DE-STA-CO Robohand's DIRECTCONNECT(TM) Double Wedge Parallel Grippers Mount without Adaptor Plates

Madison Heights, Michigan, September 6, 2006 - The DPD series of double wedge parallel grippers from DE-STA-CO Robohand features DIRECTCONNECT(TM) technology and is offered in 12 sizes covering strokes ranging from 1/16 inch to 2 inches. Grippers in the DPD series exert grip forces ranging from 12 lbs. to 400 lbs. and fall into two distinct families - the DPDL for long stroke and the DPDS for...

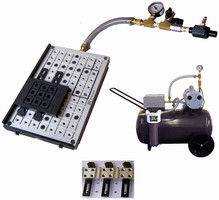

Read More »Fixture Mounting System suits automated workholding.

Combining Ball Lock mounting technology with hydraulic power, quick-change Hydraulic Ball Lock(TM) System delivers speed of hydraulic clamping with positive mechanical lock. Fixture plates are dropped onto manifold-mounted Ball Lock shanks, which are hydraulically unlocked but lock mechanically. Measuring 25 mm x .75 in., shanks will not release unless hydraulic pressure is reapplied. System both...

Read More »

Parallel Grippers withstand more than 10 million cycles.

Featuring DIRECTCONNECT(TM) technology, DPW Series can be mounted directly to other modular automation products without adapter plates. Wide body design provides secure gripping of large and wide parts. Jaws are supported throughout length of gripper body, making series suited for long finger applications. Offered in 3 sizes with 2 strokes per size, grippers can be mounted and operated in any...

Read More »

New Patented Manual Toggle Clamps From DE-STA-CO Provide Increased Ergonomics and Holding Power

Madison Heights, Michigan, October 5, 2005 - DE-STA-CO's Vertical Handle Hold-Down Action Clamps represent the next generation of manual toggle clamps. The new clamps allow users to save space without compromises in holding capacity or performance. The patented 2002, 2007 and 2010 series of Vertical Handle Hold-Down Action Clamps deliver two to three times the holding capacity of DE-STA-CO's...

Read More »

Top Design Engineering Considerations For Optical Assemblies

In this eBook, we provide an overview of the design engineering considerations to keep in mind when planning the manufacture of an optical assembly.

Read More »

CNC Workholding Systems offer operational flexibility.

Pallet-Vise may be used as stand-alone solution for machining or in multiple-pallet configuration for larger parts or high-volume production. Alternatively, Vac-Vise may be used as vacuum chuck or pallet system simultaneously to hold various workpiece shapes and sizes. Both allow machining and marking of workpieces without custom fixtures and are designed to facilitate creation of repeatable...

Read More »

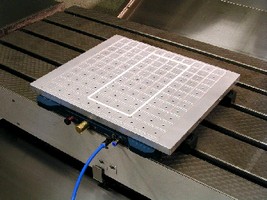

Vacmagic

Mitee-Bite Products introduces the Vacmagic, a versatile vacuum pallet changing system that runs off 70-80 psi of standard shop air, no vacuum pump required. The customer can run high volume production runs at the same feeds and speeds they normally would, with the repeatability of .0002. Swap over to a vacuum pallet for those jobs too difficult to clamp and be up and running within seconds....

Read More »

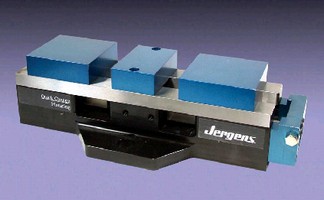

Hydraulic Vises feature quick-change jaw system.

Providing up to 4,700 lb clamping capacity, hydraulic production vises come in 3 base styles. Ball Lock(TM) Mounting System features interlocking jigsaw pattern that permits multiple vises to closely nest together; universal base style mounts directly to machine tables; and narrow base style is designed for stand-alone fixture plate mounting. Vises include machinable, reversible jaws; hardened...

Read More »

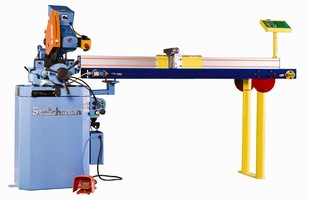

Measuring System mounts to metal or wood working machinery.

Enabling accurate setting of material length, CPO 350 ScotchmanÃ-® Advanced Measuring System allows feeding of material in 4-24 ft lengths from left to right or right to left. Loc Stop and Multi-Loc systems are manufactured using stainless steel investment casting, and do not slip.

Read More »

Clamp is designed to facilitate weld alignments.

Machined from heat-treated steel, HOG-TIE(TM) Weld Alignment Clamp delivers up to 15,000 lb of force for holding 2 boiler tubes, pipes, flanges, or plates in place. It consists of 2 clamping jaws and one steel strap. Latter is inserted between 2 sections being aligned, engages clamping jaws, and pulls them together using wrench. Design accelerates setup and releases instantly, while allowing...

Read More »New Live Tooling on Display at IMTS

Wheeling, IL- SMW Autoblok will display a new line of Live Tooling at IMTS in Booth E-2207. This complete line of live tools provides increased machine utilization of turning centers resulting in more parts per hour. Standard tooling models feature straight, angle or dual heads and are in stock to fit most popular OEM Turning Centers with motorized turrets. Like all their workholding products,...

Read More »

New Davenport Hybrid Machine Offers Unique Flexibility for Parts Manufacturing

The Davenport Hybrid machine offers greater flexibility, easier set-ups, and faster cycle times. Check out the video to learn more.

Read More »