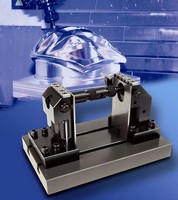

Clamping System is designed for 5-axis machining centers.

Press Release Summary:

Providing up to 40 kN clamping force, Model VB 5 AX 100 allows high speed, continuous 5-axis cutting motion of sculptured surfaces, pockets, and other 3D features in single clamping setup. System eliminates jaw deflection and/or part misalignment during machining operations. Features include clamping width of 2-236 mm, clamping depth of 8 mm, and height above machine table of 175 mm with extended height options to 200 and 225 mm.

Original Press Release:

Kurt to Show New Clamping System for 5 Axis Machining Operations at IMTS '06 Booth E-2749

Minneapolis, Minnesota: Kurt announced today another workholding first to be introduced at IMTS '06 - the new VB 5 AX 100 clamping system for the latest 5 axis machining centers.

Now, machine on 5 sides with one single clamping operation using the Kurt VB 5 AX 100 clamping system. This patented clamping system provides up to 40 kN clamping force for obstruction-free machining on five sides. It allows high speed, continuous 5-axis cutting motion of sculptured surfaces, pockets and other 3-dimensional features in a single clamping setup.

"This new Kurt VB 5 AX 100 clamping system addresses another advanced technology area of the machining industry," reports Steve Kane, sales manager for Kurt Industrial Products. "This is especially true in the high-tech world of aerospace and automotive design where turning to 5-axis machining is a means to speed manufacturing and increased repeatable accuracy. The ability to machine complex shapes, undercuts and difficult angles in a single setup reduces tooling cost and labor time, resulting in a better cost per part in addition to maintaining repeatable accuracy throughout the part run."

The new Kurt VB 5 AX 100 clamping system is designed to eliminate jaw deflection and/or part misalignment during machining operations. The system will handle blank work pieces, machined work pieces, and round and irregularly shaped work pieces easily with repeatable accuracy. The system is adjustable to handle any desired clamping width, limited only by the size of the machine table. The system's two clamping jaws, one stationary and one moveable, can be positioned at any desired distance from each other.

Basic specifications of the Kurt VB 5 AX 100 are: clamping force 0 - 40 kN; clamping width 2 - 236 mm (can be extended with optional spindle screws); clamping depth 8 mm; height above machine table of 175 mm with extended height options to 200 mm and 225 mm. Mounts easily on standard T-slot tables, location grid machine tables or any custom fixture.

The Kurt VB 5 AX 100 clamping system is the latest addition to the VB DockLock® Zero-Point Workholding System marketed in the United States, Canada and Mexico by Kurt in partnership with its manufacturer, Vischer & Bolli of Dubendorf, Switzerland.

See the Kurt VB 5 AX 100 demonstrated at IMTS '06 Booth E-2749. Kurt is a "must visit" booth for the very latest in precision machining workholding technology, September 6-13, McCormick Place, Chicago, Illinois.

www.kurtworkholding.com

Email: workholding@kurt.com

Kurt Manufacturing Company,

Industrial Products Division,

1325 Quincy Street NE,

Minneapolis, Minnesota 55413.

In USA and Canada call 1-800-328-2565

Outside USA and Canada, call 1-763-572-4424.

In USA, Fax 1-877-226-7828.

Outside USA, Fax 1-612-623-3902.