Wire Feeder uses MaxTrac(TM) heavy-duty wire drive system.

Suited for MIG and metal- or flux-cored wire welding, LF-74 delivers positive arc starting and feeding with stainless steel and aluminum. Its 4-roll MaxTrac(TM) cast aluminum wire drive system delivers consistent feeding force. Accommodating 0.023-1/16 in. MIG wire diameters and .030-5/64 in. flux-cored wire diameters, unit offers feed speeds of 50-800 ipm. Split wire guides provide full support...

Read More »Die Feeder is optimized for handling small flip chips.

Able to feed variety of bare die and flip chips, DDf Ultra can be mounted on most placement machines. It is capable of feeding die down to 0.5 x 0.5 mm, with throughput exceeding 6,000 die/hr. By combining DDf Ultra with SMT chip shooter, users can create die shooter or flip chip shooter for complete die assembly solution.

Read More »Feeders are compatible with Siemens Siplace-® machines.

Tape feeders, available in 12/16, 24/32, 44, and 56 mm sizes, employ reversible index drive that facilitates component changeovers. Along with high-visibility status indicators, products feature modular design and software diagnostic feature set with pick point calibration. Pre-printed label feeder, LPS, and print-on-demand label feeder, POD600, are also compatible with Siplace placement machine...

Read More »

Automatic Bar Feed offers 4 minute changeovers.

Using oil-based, hydrostatic support system, Quick Six handles 18 in. to 6 ft long bar stock ranging from 5/16-3 1/8 in. diameter. Menu-driven remote control prompts users through setups, and program data is stored on smart media cards. Standard chain magazine holds 8 pieces of bar stock, and optional side load rack and bar elevator holds up to 50 6-ft bars.

Read More »

What Affects the Price of Electronics Manufacturing?

The eBook provides an overview of designing for manufacturability, exploring what it means and discussing what to do to design costs out of electronic manufacturing projects.

Read More »

Process Controller suits seam welding of thin gauge metals.

CSC MIG welding controller utilizes controlled short circuit gas metal arc welding process to clear short circuits by retracting wire from short. Controller syncronizes wire feeder actions with power supply current to continuously feed wire alternatly between forward and reverse directions. Process helps to increase travel speed and eliminate spatter on wide range of materials including steel,...

Read More »

Friction Feeder System handles items down to 1.5 in.-²

Micro Rapid IN-Feeder intelligently inserts material into carton or tote or directly on product as it passes on conveyor. With feed rate up to 12,000 inserts/hr, unit offers variable speed capability, adjustable height mounting, and precision placement of product. Tip-On feeder handles material sizes to 7 x 9 in. and supports materials such as catalogs, paper, coupons, phone cards, credit cards,...

Read More »

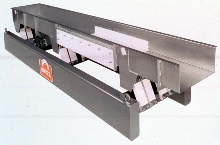

Vibratory Feeders and Conveyors transport bulk materials.

Model HVF 2-mass vibrating feeder delivers flow rates to 100 fpm. With single-mass design, SM Conveyor moves loads of free-flowing materials up to 50 lb/ftÃ-³ at rates to 25 ftÃ-³/min. Tuned 2-Mass Model(TM) mechanical conveyor has 75 lb/ftÃ-³ and 35 ftÃ-³/min capacities, while Model HVC moves bulk materials up to 100 lb/ftÃ-³ at rates to 60 ftÃ-³/min. VMC Series...

Read More »

Hopper Feeder feeds various lengths of lumber.

TylerÃ-® Endless Belt Hopper Feeder Model 4011 is 12 ft long and has fabricated steel frame with adjustable legs that allow for off-bearing height range of 32-37 in. Standard feeder capacity is Ã-½-2 in. thick, Ã-½-12 in. wide, and minimum of 8 in. long stock. Feeder has adjustable speeds from 50-200 fpm. Adjustable, pillow block mounted pulley maintains belt tension and tracking....

Read More »Welding System is available in various configurations.

Ready-Pak(TM) kits are available in 4 configurations with various power sources to meet application needs. All kits include LF-72 wire feeder featuring 2-roll MaxTrac(TM) drive system for accurate wire feeding. Other components are power source, drive rolls and wire guide, wire feeder control cable, welding gun, work lead and clamp, and HarrisÃ-® Flowmeter/Regulator and gas hose. Two kits...

Read More »Dispenser is suited for compound management and logistics.

FlexiWeigh 1000 and 2000 offer capabilities for powder and solvent dispensing, inerting of target containers, and capping/uncapping in addition to labeling, sample tracking, and weighing. Floor-standing, fully enclosed cabinets are equipped with XYZ robot with rotating arm and WISC module, which can combine multiple operations at one vial position. Optimally suited for powders in 1-20 mg range,...

Read More »

General Pipe Cleaners Presents Lightweight, Powerful JM-1000 Mini-Jet

The lightweight, compact JM-1000 Mini-Jet clears grease, sand, and ice with a high pressure water jet.

Read More »