Vibratory Feeders suit complex material feeding tasks.

Utilizing Hi-Vi magnetic drive circuit and AC controls, vibratory feeders are able to handle materials from micron size to bulky chunks. They also feature totally enclosed, dust and moisture-resistant magnetic drive that extends coil life and facilitates external cleaning. Single feeders or groups of feeders can be controlled from one station, and controls with solid-state components are...

Read More »Spreading Feeder offers instant start/stop.

Dual-drive, vibratory dosing feeder and storage hopper features infinitely adjustable potentiometer, which offers 0-100% feed rate control and allows extremely fine trickle of material. It is suited for spreading applications and processing of dry bulk food products, feed/grain, and chemicals. Feeder can be engineered to specific application requirements.

Read More »

Roll Feeds handle thin stock with -

Waddington LD Series features brushless, low-inertia servo motor and closed-loop brushless feedback for absolute position feedback. Coupled with 2 in. dia smooth steel finish rolls; heavy-duty dowel pinned frame; permanently lubricated, anti-friction bearings; and anti-backlash gears between top and bottom rolls, products handle thin stock at speeds to 1,000 SPM. They come in sizes for stock...

Read More »

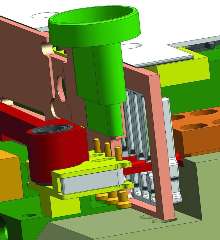

Feeder uses flex cell placement equipment.

Multi-Pick Feeder enables standard placement cells to pick and place multiple discrete interconnect pins in one cycle. It translates 24 mm tape carrying discrete pins from horizontal to vertical orientation, while ejector uses single motion to push multiple pins into retainer. Feeder mechanism can also make pitch adjustments up to 1-2 mm as pins are transferred from tape to retainer. Feeder waits...

Read More »

Metal Stamping for Construction Tool Applications

Metal stamping is a highly versatile manufacturing technique, capable of producing quality components at tight tolerances.

Read More »

Screwless Feeders accurately dose masterbatch or additives.

Utilizing induced flow rotating cone, Micro Feeder B110 can dose down to a few granules at a time and up to 6.6 lb/hr of normal masterbatch. Posimax B200 employs positive displacement feeding and has only one moving part. Materials are fed via rotating channel, delivering true mass flow as materials are displaced from inlet to outlet. Intended for plastics processing, both feeders are pre-wired...

Read More »

Bulk Solids Pump Feeder is available in 3 models.

Available in gravimetric, volumetric, and loss-in-weight models, Bulk Solid Pump (BSP) feeders utilize positive displacement to feed free-flowing materials. They offer uniform discharge, consistent volume, and gentle handling. Vertical rotating discs create product lock-up zone, smoothly conveying material from storage hopper to discharge outlet and achieving true linear mass flow. Feed rates...

Read More »

Wire Feeder suits modular, multi-process use.

Digitally-controlled, Power Feed(TM) 10M features 4 drive rolls and optional push-pull capability for aluminum welding. Using Nextweld Waveform Control Technology(TM), each weld mode meets standards for low spatter, weld bead profile, and arc shape. MSP4 user interface panel controls all parameters including weld mode selection, arc control adjustments, weld sequence, limit setting, and lockout....

Read More »

Feeder dispenses books onto flat conveyor.

Using vacuum approach to pick books from top of stack and place them on flat conveyors, Gemini book module offers continuous flat feeds rates to 70 books/min. Dual side-by-side loading trays allow operator to simultaneously load one side of module while dispensing from other. Able to handle books from 4 x 4 x .125 in. to 21 x 14 x 4 in., product is suited for order fulfillment applications.

Read More »

Wafer Feeder offers on-line wafer expander option.

Wafer Feeder is compatible with industry-standard wafer sizes, including 12, 8, and 6 in., and accepts full 25-wafer cassettes. It combines programmable die ejection, theta correction and expansion with wafer mapping and ink dot recognition, bar code identification, and tracking of wafers to handle complex dies in 300 mm format. Use of parallel processing has pared tact time as low as 1 sec/ die....

Read More »

Volumetric Screw Feeder features direct drive.

Metatech(TM) provides accurate metering of powders, pellets, flakes, and agglomerates. It features 2 or 3 moving parts, depending on screw size; O-ring seals for dust-free operation; and TeflonÃ-® rear seal. Interchangeable screw/tube combinations from 1-6 in. permit feed rates from 0.3-550 cu-ft/hr. Agitator/conditioner screw completely fills feed screw for accuracy of Ã-

Read More »

Increase Workplace Safety, Manage Heavy Loads with Equipment from A-Plus Warehouse

A-Plus Warehouse carries a wide selection of commercial and industrial material handling equipment at affordable prices. Check out the video to learn more.

Read More »