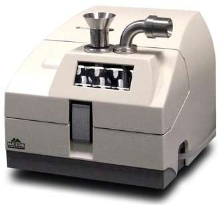

Self-Feeder has labor- and time-saving design.

Compatible with any Ã-½ and 3/8 in. shaft and casing, Wils-Matic(TM) Self-Feeder is designed for cleaning straight tubes up to 45 ft long in heat exchangers, condensers, chillers, absorbers, and coolers. It requires no special brushes or shafts and features auto teach mode, 1 hp motor, and auto-reeling shaft storage. With 125 lb net dry weight, machine has 4.2 fps self-feed rate and 50 lb...

Read More »

Portable Wire Feeder includes Soft Start(TM) run-in control.

Voltage-sensing SuitCase(TM) X-TREME(TM) 12VS holds wire spools up to 12 in. and features SunVision(TM) digital meters that display voltage and wire feed speed or amperage, and are visible in direct sunlight. Two drive rolls provide positive feeding with solid wires from .023-5/64 in. and cored wires from .030-5/64 in. Featuring polypropylene case, feeder operates on arc voltages from 14-48 Vdc...

Read More »

Bottom Dispensing Feeder handles CDs, DVDs, and videos.

Model SPS-200 Inductor dispenses CDs, DVDs, videos, and paperback books at rates of 225 items/min. Available with stand-alone or integrated controls, unit features top-loading design for dispensing onto flat conveyors, and ability to load different size rectangular items at same time. Multiple feeders can be ganged together and bolted directly to conveyor for high throughput requirements.

Read More »

Gravimetric Feeder handles plastic pellets and regrind.

Consisting of 1-8 feeders and central microprocessor-based controller, ProRate(TM)/Gravimetric Feeder continuously meters raw materials into central station hopper. Each feeder operates in independent, continuous loss-in-weight scaling mode to insure accuracy of each ingredient. Controller monitors weight signals of each feeder and adjusts auger speed to match recipe feed rate. Unit controls 1-8...

Read More »

Access Hardware: Medical Solutions

This guide will provide a closer look at solutions for medical equipment and devices

Read More »

Bar Feeder handles various sizes and shapes of bar stock.

By changing feed tube size, RHINOBAR can be customized for virtually any size bar stock. Tube sizes range from Ã-¼-2Ã-¾ in. in 1/8 in. increments, accommodating bar stock diameters from 1/8-2Ã-¾ in., and up to 12 ft long. Pedestal and barrel clamps provide stability, preventing whip or spin of bar. Oil fills gap between bar stock and feed tube, acting as noise damping support....

Read More »

Bar Feeder utilizes hydrodynamic forces for operation.

Mini-Rhinobar single-tube bar feeder is engineered for Swiss type CNC screw machines and small, fixed-head CNC lathes. Oil fills gap between bar stock and feed tube, acting as noise damping support. Oil flow and pressure are controlled with single valve, which also allows for accurate bar control and minimizes vibration. Mini-Rhinobar can be controlled from remote pendant for safe operation. Feed...

Read More »Volumetric/Weigh Feeder offers simplified functionality.

Able to feed granular and powdered materials, Series 58QP has front cover that removes without tools in order to facilitate inspection and cleaning. Series is also equipped with direct feed auger drive, NTEP weighing system, digital weighing system, and 4.5 x 3.5 in. LCD display capable of tracking up to 12 independent feeder systems. Metering capacity ranges from 20-5,000+ lb/hr, and products...

Read More »

Dry Powder Feeder aids in cement particle sizing.

Compatible with Mastersizer 2000 laser diffraction-based particle size analyzer, Scirocco 2000 meets sample dispersion needs for measuring cements and other abrasive bulk chemicals. Design facilitates routine, reproducible dry powder analysis and allows for manual or automatic operation. Unit includes vibrating hopper feed system and predefined SOP that controls sample delivery, dispersion, and...

Read More »

Smart Feeder Retrofit Kit utilizes RFID technology.

Usable on different machine types, RFID Smart Feeder system can be retrofitted to existing placement machines. It converts feeders into smart feeders by attaching RF tag to each feeder that enables closed-loop feeder and component setup validation. Product provides real-time material inventory and traceability while proactively scanning all feeder slots in real-time. System can be used in...

Read More »

Prefeeder/Wire Payout works with cutting machines.

Dependent upon material condition, Model APF100 is designed for wire sizes .030-.312 in. and can be used with any Wire and Tubing Cutter or Cut and Strip Machine. Unit prevents material overruns when used with intermittent feed machines. Offering max drive speed of 100 ips, free-standing device accommodates reels up to 18 in. in diameter and 12 in. in width.

Read More »

Precision Fabricating with Over 40 Years of Experience

Quality Sheet Metal specializes in delivering precision, value, and customer service. With a client base that spans many diverse industries and a reputation for excellence that goes back over four decades, our clients know that we can provide the optimal combination of value and flexibility regardless of the challenge. See our video to learn what we can do for you. Through investments in state-of-the-art design, manufacturing, and quality control systems, Quality Sheet Metal remains focused on maintaining a high standard of quality, customer service, and competitive pricing. With an emphasis on customer satisfaction, Quality Sheet Metal is dedicated to establishing long-term partnerships, similar to the ones they currently have with their valued clients. If you're looking for a new partner with extensive capabilities in sheet metal fabricating and finishing, look no further.

Read More »