Router Bits have custom-blended carbide with titanium.

Router Bits, offered in 119 models, have 1/4 and 1/2 in. shanks. Machined from high-speed tool steel, they are tri-metal brazed for impact-resistant bond between carbide and bit. Computer-balanced body eliminates vibration and chatter. Constant relief angle on entire cutting edge provides flawless finish and reduces burning. Shielded ball bearings, with high-temperature lubricant, withstand...

Read More »

Drill Bits feature X-shaped, solid carbide head.

TE-TX and TE-YX bits drill through concrete and cut through rebar. Double spiral fluting provides dust removal. Designed for use in combihammers with TE-T (SDS Top) chucks or TE-Y (SDS Max) chucks, connection ends on bits maximize power transmission and minimize strain on drilling machine.

Read More »

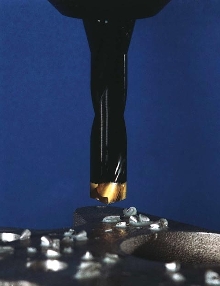

Drill Insert handles ductile materials.

UnidrillÃ-® has UC-CCR chipbreaking geometry, suitable for drilling ductile materials such as steels, stainless steels, and cast irons in range of 0.531 to 1.000 in. dia. Corner radius reduces thermal stress, improves tool life, minimizes break-out at back of hole, and improves surface finish. Clamping system ensures precise insert location, while SC7052 CVD coating allows high feed rates at...

Read More »

Spade Drilling System optimizes holder and insert performance.

Tru-Lok spade drilling system is offered in variety of straight shank, flange-type, and Morse-Taper shanks. Holders include quick change, back piloted, and combination drilling/secondary operation bars. Inserts ranging from 1/2 to 1 3/8 in. diameter are available in several grades of carbide and CPM high-speed steel, and in most common coatings.

Read More »

Plastic Knobs

Knobs - Customizable Solutions To learn more about the different types of Knob solutions available, and which ones to select for your specific application, download this guide now.

Read More »Milling Products suit die and mold industries.

CoroMill Century facemill is available in 1.5 to 6.0 in. dia and is capable of 40,000 rpm. It uses carbide or polycrystalline diamond inserts and micro-adjustable mating pockets. CoroMill 390 long-edge facemill is available in 2 to 8 in. dia and uses 18 mm long inserts for deep cuts in high-temperature alloys. CoroTurn family consists of extra-sharp, high positive rake, V-style inserts for smooth...

Read More »

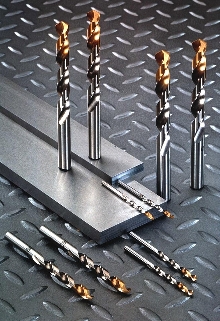

Jobber Drills feature TiN coating.

R002 solid carbide jobber drill is offered in sizes ranging from 3 to 14 mm and 1/8 to 17/32 in. dia. Range includes 29 key tap/drill sizes in fractional, letter, and gauge sizes. Flute is 25% TiN coated for increased cutting speeds, and ensures 5X diameter depth drilling capacity. A002 High Speed Steel Jobber Drill has TiN coating applied to working end.

Read More »

Jobber Drills are TiN coated.

Series A002 high-speed steel jobber drills, with TiN coating on working end and special point geometry and helix, allow for lower cutting forces than standard design, while resisting flank and crater wear. Drills are offered in metric and fractional sizes, ranging from 1.00 to 16.00 mm and 3/64 to 5/8 in., respectively.

Read More »

Drill matches brazed drill precision.

CrownLoc(TM) allows users to drill different diameters using same drill body. It features precision-ground interface of interlocking V-grooves to ensure repeated positioning of each crown. Cutting edges are produced by injection-molding carbide substrate, producing homogenous tungsten carbide. Double coolant holes through each crown permit high volume of coolant to reach cutting edge. Crowns are...

Read More »

Coring System handles asphalt and concrete.

Self-contained system includes generator, water tank, frame, manual outriggers, and high speed drill. It fits inside pickup truck or trailer. System offers multiple coring positions and is powder coated for durability.

Read More »

Cobalt-Steel Drill speeds stainless-steel production.

Made of M35 cobalt steel with TINAL FUTURA TOP coating, VA INOX drill combines aggressive point geometry and flute profile to provide cutting edges with high load bearing capacity. It is 4 times more productive than conventional HSS drills, is suitable for small to medium batch sizes typical in stainless-steel production, and does not require internal coolant supply.

Read More »

SRG Global Coatings Enhance Surface Durability, Efficiency, Design Flexibility

SRG Global's automotive coatings enhance the structural integrity of the finished part while also improving vehicle efficiency. Check out our video to learn more.

Read More »