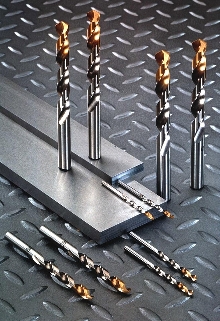

Jobber Drills are TiN coated.

Share:

Press Release Summary:

Series A002 high-speed steel jobber drills, with TiN coating on working end and special point geometry and helix, allow for lower cutting forces than standard design, while resisting flank and crater wear. Drills are offered in metric and fractional sizes, ranging from 1.00 to 16.00 mm and 3/64 to 5/8 in., respectively.

Series A002 high-speed steel jobber drills, with TiN coating on working end and special point geometry and helix, allow for lower cutting forces than standard design, while resisting flank and crater wear. Drills are offered in metric and fractional sizes, ranging from 1.00 to 16.00 mm and 3/64 to 5/8 in., respectively.Original Press Release:

Dormer Tools Adds Improved Performance Jobber Drills

for immediate release

Asheville, NC May 15, 2002...Dormer Tools has introduced the A002 High Speed Steel Jobber Drill with TiN coating applied to the working end of the drill. The TiN coated drill point, combined with advanced helix and special point geometry, allows for lower cutting forces than a standard design while resisting flank and crater wear. These new jobber drills deliver longer tool life, more accurately produced holes and increase cutting performance through most materials while meeting growing demands for higher performance from traditional jobber drills, the workhorse of general machining. The A002 is offered in both metric and fractional sizes, ranging from 1.00 mm to 16.00 mm and 3/64" to 5/8" respectively. Test results show that this competitively priced drill is already proving to be a high performance tool, outstripping the tool life of standard geometry TiN coated jobbers.

For more information on the A002 HSS Coated Tip Jobber Drill, please contact Dormer Tools at 828-274-6078 in the United States or at 905-542-3000 for Canadian customers.

Editorial Contact

Client: Wayne True, Product Manager, Dormer Tools Inc.

Tel. 828-274-6078 Fax. 828-274-6076

Agency: Ron Ward, Ward Communications

Tel. 860-676-8338 Fax. 860-676-9669