Carousel Wash System is adapted for de-oiling and chip removal.

Cell-Mate 200 is fitted with carousel return-to-front conveyor. It is built on rigid steel chassis with fork lift channels for relocation. Stainless steel fabrication of solution tank and process chambers provides resistance to corrosive, aqueous chemistries. High-impact, V-spray nozzles surround component in first process chamber, while second chamber utilizes multi-adjustable air knives that...

Read More »

Basket Washer accommodates high production requirements.

Rotary Basket Washer System is available in single or multi-stage configurations with manual or automatic load and unload systems. Basket system can be designed to accommodate various part sizes and geometries. Stainless steel tanks and enclosures provide durability and chemical resistance. Available heating systems include electric, gas, or steam. Standard units come in 2, 4, 6, 8, and 12 basket...

Read More »

Sanitary Tank Washers meet USDA, FDA, and 3A standards.

Clipdisc clean-in-place (CIP) tank washers offer hygienic design that delivers cleaning action in 360Ã-

Read More »

Parts Cleaner Exhaust System reduces moisture loss.

Exhaust Moisture Reduction System for parts cleaning systems minimizes moisture escape, enhances part drying, and conserves water, chemistry, and energy. It works with aqueous based parts washing systems that rely on spraying heated water. Exhaust system pre-warms incoming make-up water and blow-off air, and directs exhaust moisture back to solution tank. Exhaust air can be vented directly to...

Read More »

Ten Important Questions to Ask Before Selecting a Sign Company

This white paper outlines 10 questions that should be asked when selecting a sign company, eliminating some of the guesswork from making the best choice for your branding and signage needs.

Read More »

Radiator Washer reduces reject rate.

High-volume radiator washer has high velocity blow-off units that reduce cross contamination between process stages, and remove excess water from radiator's inherent dense coil to ensure complete drying capability. Full width interlocking access doors to spray wash stages facilitate maintenance. It has polished stainless steel construction, and natural gas heat for wash, rinse, and dry stages.

Read More »

Microplate Washer offers automatic bottom well detection.

MW 96 automated programmable microplate washer is for use with strips and 96-well plates. It features pressure- and vacuum-free pump system for quiet operation. Washer can be configured with up to 3 different wash liquids and will store 50 wash procedures. Intuitive software facilitates programming of wide variety of wash cycles and procedures. Dispensing volumes and speeds, aspiration speeds and...

Read More »

Belt Washer System is suitable for high-production cleaning.

Manual or automatic belt washer system is available in single or multi-stage configurations. System accommodates various part sizes and geometries using open weave conveyor belts or custom designed fixtures. Construction includes stainless steel tanks and enclosures and 1 x 1 in. stainless steel flat wire belts. Belt washer system is available with chip removal and electric, gas, or steam heating...

Read More »

Loop Tunnel Parts Washer provides multi-stage cleaning.

CellMate 200 return-to-front conveyor parts washer includes aqueous spray washing and heated air drying in small-footprint package that has fork lift channels or caster for relocation. Overall dimensions of basic stainless steel machine are 37 x 78 in. Complex components may be fixtured on conveyor to facilitate targeted impingement of spray blow-off nozzles onto hard-to-clean or hard-to-dry...

Read More »

Robotic Transporter moves parts to cleaning tanks.

Programmable TDR-50 automated hoist transport system interfaces with most multi-tank cleaning and processing tank lines and consoles. It handles up to 110 lb of load and part fixtures. Programming is via simple keystrokes, using operating codes and keypad numeric functions. It stores up to 255 steps that can be divided among maximum of 10 programs. LED display indicates operating code and X-Y...

Read More »

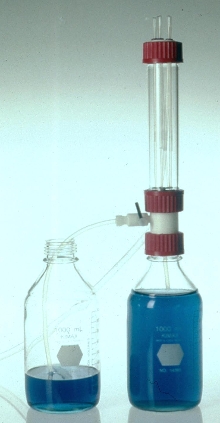

Washer/Dryer cleans 7 and 8 in. long tubes.

NMR washer/dryer accommodates 3 and 5 mm diameter tubes. All wetted parts are PTFE or borosilicate glass. Valve can be positioned for repeated or sequential wash and dry cycles. Unit is supplied complete with outlet for connection to vacuum source, 1 liter reservoir, PTFE connecting tubing, and tube O-rings.

Read More »

Neagle Choice, LLC Announces New Available Services

Neagle Choice has long been known as a quality source for commercial sewing, printing, die cutting, and the manufacturing of a wide range of custom products. Enhancing our service capabilities has been the key to our success, and has driven our growth into many new and exciting markets. Continuing on this trajectory, we now offer precision laser cutting and etching, adding to our long line of manufacturing services. See our video to learn all about it.

Read More »