Loop Tunnel Parts Washer provides multi-stage cleaning.

Press Release Summary:

CellMate 200 return-to-front conveyor parts washer includes aqueous spray washing and heated air drying in small-footprint package that has fork lift channels or caster for relocation. Overall dimensions of basic stainless steel machine are 37 x 78 in. Complex components may be fixtured on conveyor to facilitate targeted impingement of spray blow-off nozzles onto hard-to-clean or hard-to-dry surfaces.

CellMate 200 return-to-front conveyor parts washer includes aqueous spray washing and heated air drying in small-footprint package that has fork lift channels or caster for relocation. Overall dimensions of basic stainless steel machine are 37 x 78 in. Complex components may be fixtured on conveyor to facilitate targeted impingement of spray blow-off nozzles onto hard-to-clean or hard-to-dry surfaces.Original Press Release:

Looped Tunnel Wash System

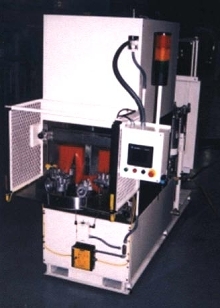

May 31, 2002 - Saratoga Springs, NY - Guyson Corporation, booth #4675 in the Lakeside Center at IMTS, is introducing its CellMate 200 return-to-front conveyor parts washer, an ultracompact multi-stage cleaning system for the work cell. The unit includes aqueous spray washing and heated air drying in a small-footprint package that has fork lift channels or casters to simplify relocation in flexible manufacturing operations.

Overall dimensions of the basic stainless steel machine are 37" x 78" (1 m x 2 m). Extra fine filtration, oil skimming, a rinsing stage and numerous sensor and control features are available options. Complex components may be fixtured on the conveyor to facilitate targeted impingement of spray blow-off nozzles onto hard-to-clean or hard-to-dry surfaces.