Aqueous Parts Washer provides continuous cleaning.

Single-stage, pass-through parts washer, Model 8600, features 16 in. wide steel conveyor belt that moves at speeds to 8 fpm, carrying parts through wash tunnel where they are blasted with hot water spray from 360Ã-

Read More »

Parts Cleaning System suits low volume applications.

Utilizing non-halogenated hydrocarbon process, Minio 85C removes oil, grease, and swarf from metal, plastic, or glass. Typical throughput is 5 or 6 baskets/hr with max weight of 110 lb/batch. With footprint of 39 x 79 in., closed loop system offers continuous filtration and recirculation, and operates under vacuum with virtually no emissions. It provides injection flood washing, vapor degreasing,...

Read More »

High-Pressure Washer provides controlled cavitation.

Designed to clean machined parts of cutting fluids and loose chips, U-Jet(TM) III washes up to 6 sides of complex components. Triplex pump produces water pressure to 1,015 psi and delivers it at max flow rate of 13.0 gpm and sonic velocities to 1,100 ft/sec. All washing/cleaning operations are controlled via Mitsubishi PLC controller. Unit incorporates horn nozzle design, and workspace...

Read More »

Ultrasonic Cleaning Module enables wire/tape cleaning.

Series USCM System cleans ferrous, non-ferrous, copper, high/low-carbon steel, glass, and plastic. It removes oil, grease, stearate, soap, and dust and is capable of single-strand and multiple-strand cleaning. Each system includes SS liquid tank, air wipe for final drying, control cabinet for ultrasonic generators, and PLC. Choice of 5 different ultrasonic processors is offered, from 250-4000 W....

Read More »

Managing the New FGD Wastewater Regulations

A guide for managing Flue Gas Desulfurization wastewater using leading technologies.

Read More »

Water Deburring Center allows multi-part processing.

Jet-Clean Center 4-axis high-pressure deburring center clears chips and burrs from machined components. Large 20 x 12 x 12 in. XYZ-work area permits large part capacity and/or multi-part processing. Using 5,000 psi water and nozzle technology, unit blasts and dislodges compacted chips and debris from blind, tapped and cross holes and passages. Traveling at sonic velocities to 1,100 ft/sec, water...

Read More »

Parts Washer removes chips and burrs on small parts.

Stainless steel Model IPW-1000 aids in preparing parts for final cleaning by partially removing coolant, grease, and oil. Accommodating parts from Ã-¼-5 in. long and up to 45 lb per load, washer includes front panel controls with 0-15 min timer, automatic lid closer, and protective motor shroud. Removable cleaning basket has internal baffles and 1/8 in. holes. Washer can be used with mineral...

Read More »Gasoline-Direct Drive Washer utilizes pressurized hot water.

Series HSP portable, self-contained hot water pressure washer utilizes Electro Magnetic Firing system that eliminates need for blower motor, transformer, alternator, battery, or generator. Features include top-fired dual spiral coil with powder coated heat exchanger, direct drive triplex ceramic piston pump, built-in low pressure detergent injection, pressure and high limit safety controls, and...

Read More »

Automotive Parts Washer uses magnets to clean coolant.

Cleaning system is designed for parts washing of machined automotive cast iron components. It incorporates magnetic conveyors and magnetic filtration separators along with bag filters and mist filtration units. Magnetic system cleans machining coolants to 20 micron levels before bag filter media. Unit can be incorporated with production CNC machines for chip processing and coolant cleaning.

Read More »

Machinery cleans machined parts of complex geometries.

Aquamate RF rotary fixture parts cleaning system can clean high volume screw machine parts in baskets or low volume machined parts with complex geometries. For highly complex parts with blind holes and multiple passageways, pneumatically actuated probes can be incorporated to wash specific part features. Multiple sensors ensure precise part positioning and highly accurate probing for cleaning...

Read More »

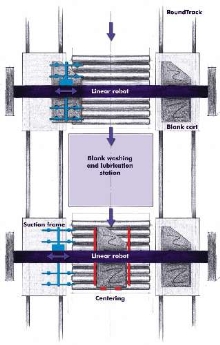

Blank Washing System can feed several press lines.

Stand-alone Blank Washing System consists of conveyor belt that transports blanks through washer and lubricator, 2 high-speed shuttles, 4 blank carts that run on RoundTrack-® in-floor rail system, and centering station. Detached configuration allows press line to run during washer stoppages. SRLS 2/120 material handling robots enable acceleration rates up to 1,120 m/s-², velocities up to 5.5...

Read More »

ISO-Certified Plastic Injection Molding from Rodon

The Rodon Group is a proven leader in high-volume, close tolerance injection molding. We offer globally competitive, innovative manufacturing solutions for a broad range of industries. Check out our video to learn more.

Read More »