In-Line Sifters achieve capacities up to 1,000 lb/min.

Tru-Balance Sifters are inserted into vacuum or pressure pneumatic conveying lines as quality assurance tools for removing small amount of oversized impurities from product. They utilize pneumatic sieve compression system to elevate and lower upper dome assembly. Systems offer rapid access for sifter inspection, have no heavy domes to lift or hoist, and provide accelerated sifter closing. All...

Read More »

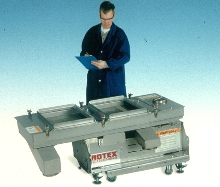

Pellet Screeners provide removal of off-size material.

Plastic Pellet Screeners are offered in models with capacities up to 3,000 PPH and 5,000 PPH. They utilize horizontal, gyratory/reciprocating motion, and Dual Velocity drive with positive displacement stroke to achieve removal of oversize and longs. Long pellets remain flat on screen deck and cannot upend or pass through screen. Final product can be up to 99% free of longs 3/8 in. to 2 in....

Read More »Dewatering System drys, cools, and screens.

Model 400 integrated, multi-step system for pelletizing lines combines dewatering, drying, cooling, dedusting, and screening into single unit. It delivers product moisture levels at 0.04% in nylon applications and 0.10% in polyethylene, polystyrene, polypropylene, polyvinyl chloride, polyesters, polyurethanes and other commodity and engineering resins. Suitable for friable, glass-filled, and...

Read More »

Vibratory Screener includes variety of deck options.

Syncro-SieveÃ-® provides fixed-rate separation of dry material by size, and is also effective for wet separation. Eccentric-weighted rotary motor creates vibratory motion. Flow patterns and retention time on multiple screen decks can be varied, depending on how eccentric weights are positioned. Circular Syncro-Sieve is available in 24, 36, 48, and 60 in. dia, and can include up to three decks...

Read More »

Reducing Risk Through On-Demand Manufacturing

Check out this white paper to learn how putting manufacturing safeguards in place stimulates growth and reduces risk in your supply chain.

Read More »

Screening Station accelerates manufacturing processes.

Bag-dumping/screening station examines bagged materials for lumps and foreign matter before they enter manufacturing processes. Self-contained station includes low-profile separator, hood with vent, heavy-duty bag-support screen, and stand. Optional magnet,built into product discharge, is available.

Read More »

Vibratory Screeners sort materials as fine as 200 microns.

MEGATEX(TM) 100 Series is for screening sand, salt, soybeans, rice, limestone, potash, slate, plastic pellets, roofing granules, and urea. They are available in two sizes and two configurations: M2120 model has 120 sq ft of total screen area while three-deck M3180 model has 180 sq ft of total screen area. MG configuration, for applications as fine as 850 microns, handles capacities of 200 to 500...

Read More »

Separation System suits septage, food, and pulp products.

SPIRALIFT(TM) SR receives, screens, and separates solids from liquids. It incorporates fine screening shaftless screw system, spray wash, optional press zone, and integrated controls. System is housed in stainless steel tank enclosure with quick disconnect inlet flange for connection to septage trucks. Automatic inlet valve regulates internal fluid level. SPIRALIFT SR is available with one, 2,...

Read More »

Process Screener separates materials fast.

MEGATEX(TM) gyratory screener provides 100 to 350 sq ft of screen surface in 10x10x12 ft machine. It evenly splits and distributes incoming material to multiple, stacked 5 x 7 ft screen decks at rates up to 1,000 ton/hr. It uses 2-bank, multi-level screen deck, which keeps bed depth low and maintains screen accuracy and efficiency at high capacities. Screener can handle industrial minerals, dry...

Read More »

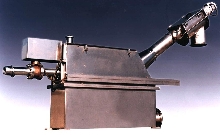

Vibratory Separator allows quick screen changes.

Pneumati-Sifter, with Air-Lift device to allow rapid disassembly, uses twin-screen decks for in-line pneumatic scalping or dedusting of up to 60,000 lbs/hr of bulk material. It also removes oversize particles from plastic resin, flour, starch, sugar, and food and chemical products gently. Applications include loading and unloading of trucks and railcars, and conveying of material between process...

Read More »

Screening System fits base machines up to 60,000 lbs.

Trommex Rotary Screener accepts mesh screens ranging from 3/4 to 12 in. spacing. Self-contained unit has anti-spillage plates at open end, lifting bars to maximize screening area, remote grease points with easy access, as well as fully machined surfaces. Trommex can convert to mixer for cement or contaminant stabilization. Relief valve only requires 20 gpm, accommodating all hydraulic pressure...

Read More »

Krueger Sentry Gauge Announces the Release of Two New Chemical Sight Gauge Models Designed for Aggressive Liquid Storage Monitoring

Krueger Sentry Gauge, a leader in chemical sight gauges, now offers the ultimate in aggressive liquid storage monitoring devices. From sulfuric and hydrochloric acid to bleach, and acetone, our products are designed with robust features that deliver a long and trouble-free service life. See our video to learn all about this new and innovative line of sight gauges.

Read More »