SCC-Screeners help pipeline operators meet US advisory.

Stress corrosion cracking screening process, SCCScreen(TM), offers oil and gas pipeline operators means of complying with US Office of Pipeline Safety advisory to evaluate SCC-susceptible lines. Adopting select aspects of in-line inspection and direct assessment, 3-phase process uses Ultrascan crack detection tool for liquid pipelines and combination Magnascan and Transcan runs analyzed with...

Read More »

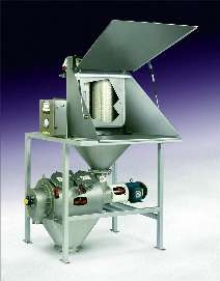

Centrifugal Screener includes bag dump station.

Stainless steel Centri-SifterÃ-® removes bag scraps and other oversize contaminants from manually dumped bulk materials while protecting operator and plant environment against dust contamination. Configured for installation on mezzanine, system gravity-discharges into process equipment. Ambient air and dust is drawn onto exterior of 2 cartridge filters that derive vacuum from top-mounted...

Read More »Centrifugal Sifter suits large process applications.

Suited for handling powders, granules, agglomerates, and other free-flowing materials, Centrifugal Sifter processes particles ranging in size from Ã-¼ in. to 44 microns. Rotating blades' spreading action distributes product around sieve cylinder for complete utilization of screen area and conveys oversize particles to discharge. Sifter operates quietly, and is totally enclosed with access...

Read More »

Rubber Screen Media features self-cleaning action.

Designed with molded, tapered openings, Dur-X-Kleen Media eliminates impact damage, plugging, and blinding. It is available in number of harder or softer rubber designs and offers abrasion and tear resistance. Dur-X-Kleen is suited to applications that involve dry, high impact material or fine, sticky or near-size material. It comes in variety of mounting styles and can be custom-designed in...

Read More »

How to Select a Rubber Compounding & Mixing Supplier

To learn more about rubber compounding and mixing, and how experienced manufacturers like AirBoss can meet your needs, download this whitepaper now.

Read More »

Ultra-Sanitary Screener features gap-free design.

Meeting cGMP, 3-A, USDA, and FDA standards, VibroscreenÃ-® includes domed lid, continuous weld seams, crevice-free interior, and washable underside. Wire mesh screening is offered in 304, 316, and magnetic 400 Series stainless steel. External interlocking flange configuration of frame envelops support ring of screen, allowing wire mesh to extend to interior walls of frame, eliminating gaps....

Read More »

Grinder/Screener handles heavy institutional waste.

Provided with up to 15 hp motor and drive, SPIRALIFTÃ-® SL 19 combines TASKMASTERÃ-® shredder and oversized channel auger screen for handling solids such as prison garb, bedding, sheets, and heavy knotted items that choke and stall lighter duty systems. Auger is powered by shaft-mounted reducer with 2 hp motor. Screens are available with 3-12 mm perforations. As effluent is discharged,...

Read More »

Mobile Screener simultaneously sorts 3 sizes of material.

Powered by Honda V Twin engines, Screen Titan utilizes incline shaker system for minimal material clogging. It features steel construction and totally mechanical systems. Screen Titan Ultra can be hauled with 1 ton truck and is designed for excavator to load and front-end loader to remove material from recovery areas. It screens and sorts over 125 yd/hr. Designed for skid steer, Screen Titan Mini...

Read More »

Screeners are suited for fertilizer industry.

Rotex Screeners deliver consistent particle size control utilizing gyratory-reciprocating motion with near horizontal screen surface combined with positive screen mesh cleaning system. Product line includes 100 models ranging from 1-5 screen surfaces for separations with openings from Ã-½ in. to 325 mesh. It is suited for use in production, polishing, and various points of distribution,...

Read More »

Screening Media prevents blinding in moist applications.

Abrasion- and tear-resistant Dur-X-Ultra Flex is made of proprietary rubber formula that delivers flexibility needed to prevent sticking problems and keep wet materials from blinding over screens. Used in medium- and light-duty applications, self-cleaning rubber screen does not require stopping of production to unplug screens. Available in modular or tensioned screens, it is offered with square...

Read More »

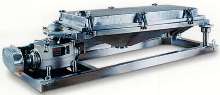

Gyratory Screeners target fertilizer industry.

Mega Screeners provide 120-350 sq-ft of screen surface in 10 x 10 x 12 ft machine. They use 2-bank, multi-level screen deck arrangement to present 16-50 ft width to feed, which keeps bed depth low. Design evenly splits and distributes incoming flow of material to multiple screen decks that combine to equal bank of 10 screeners in one machine. Machines allow quick screen changes, which is...

Read More »

Custom Fabrication & Machining Services with Over 30 Years of Experience

As a trusted manufacturer to customers across a broad range of industries, Key Gas Components is a premier provider of CNC machining and tube fabrication. Our entire organization is quality driven and customer-centric, with broad-based manufacturing capabilities that can accommodate the most challenging requirements. See our video to learn more.

Read More »