Sanitary Batch Sifter is FDA-, USDA-, and cGMP-compliant.

Dust-tight Batch Sifter, constructed with stainless steel housing, motor, and stand, is offered in 18, 24, and 30 in. dia and can be equipped with single or twin imbalanced-weight gyratory motors. With gap-free flange arrangement, unit scalps oversize particles down to 38 microns from dry bulk powders or solids-laden slurries and may be disassembled without tools for sanitizing. Wire mesh...

Read More »Screener offers optional aspiration doors.

Measuring 10 x 10 x 12 ft, MEGATEX(TM) Screener provides 100-350 ftÃ-² of screen surface and evenly splits and distributes incoming flow of material to multiple, stacked 5 x 7 in. screen decks. Optional aspiration doors remove troublesome chaff that can contaminate surrounding environment and clog other pieces of equipment during load-out process. Doors can be built into new machine or...

Read More »Blinding Control System helps screen sticky, fine powders.

Designed to minimize blinding and bridging when screening difficult or sticky materials, Ultrasonex(TM) screens through meshes as fine as 20 Ã-µm. Transducer probe applies ultrasonic vibration directly to screening mesh in addition to vibratory motion of screener. Fully detachable probe incorporates titanium core for non-wear on contact surfaces. Featuring touch panel controls, Ultrasonex is...

Read More »Separator suits industrial sand applications.

Designed to maximize product recoveries at material temperatures up to 400Ã-

Read More »

Application Selection Guide: Choosing the Right Air Compressor

Choosing the right air compressor for your application is essential, but it can feel overwhelming. To learn more about how to make the right choice, read our eBook.

Read More »

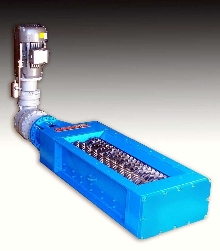

Screenings Conditioner grinds, washes, and dewaters.

SPIRALIFT SC adds benefits of in-channel auger screening system to existing mechanical bar screen installation. Bar screen automatically removes solids from liquid channel and deposits them by gravity into SPIRALIFT SC hopper. Solids are reduced to small size by TASKMASTERÃ-® grinder, and are then washed to remove contaminants and organics, compacted, and conveyed from system by shaftless...

Read More »Centrifugal Screener includes integral bag dump station.

Configured for installation on mezzanine, Low Profile Centri-Sifter(TM) removes oversize contaminants, de-lumps manually dumped bulk materials, and gravity-discharges into process equipment. Centrifugal action created by rotating helical paddles accelerates rate at which particles pass through horizontal screen cylinder while de-lumping soft agglomerates. Bag Dump Screener is stainless steel and...

Read More »Sanitary Batch Sifter features gap-free screen frames.

Equipped with single or twin imbalanced-weight gyratory motors, VIBROSCREENÃ-® scalps oversize particles as small as 38 microns from dry bulk materials or solids-laden slurries. It meets cGMP, 3-A, USDA, and FDA standards and can be disassembled without tools for sanitizing. Offered with wire mesh screening in 304, 316, and magnetic 400-series stainless steel, unit is offered in 18, 24, and...

Read More »

Fluid Bed Dryer-Screener System utilizes constant airflow.

Circular Vibratory Fluid Bed Dryer-Screener System reduces bulk material moisture content, removes agglomerates and dust, and discharges on-size material into bulk bags. It consists of 18-84 in. dia circular fluid bed processor, heater, blower, and 18-100 in. dia circular vibratory screener. Vibration, induced by 2 vibratory motors and spring suspension, separates and fluidizes individual...

Read More »

Screening Grinders suit wet, dry, or submerged applications.

Suited for heavy, solids-laden wastewater applications, TASKMASTER TM1600 Grinders process gravity or conveyor fed sewage screenings and provide in-channel grinding as well as bulk solids shredding. Twin-shaft Model TM1634 features 16 x 34 in. cutting chamber, right angle planetary gear reducer, and counter-rotating shredding mechanism employing cutter cartridges. Hardened alloy 2Ã-¾ in....

Read More »

Modular Screening System suits aggregate/mining industry.

Molded in urethane, dual-durometer urethane, or 40-60 durometer rubber, Dur-X-SnapdeckÃ-® 2000 features attachment system that facilitates modular screen installation and allows retrofitting to existing screen boxes. There are no pins, sleeves, intermediate strips, or extra parts required. Openings range from 0.3 mm slot to 3.0 in. square. Optional diverters, flow restrictors, and dams are...

Read More »

Tekna Manufacturing LLC Announces NFPA 99 Compliant Model 7200 Multiplace Chamber

Tekna is a leader in Monoplace and Multiplace Hyperbaric Chambers for Hyperbaric Oxygen Therapy (HBOT), offering products that set the standard for quality and innovation. Our new 7200 series of multiplace chambers is a state-of-the-art system that integrates advanced engineering with a plethora of features and options making it the industry's premier HBOT system. To learn more, see our video.

Read More »