Pneumatic Conveyors handle high-capacity jobs.

Series HC Semi-Dense Phase Conveyors use only positive air pressure for vacuum loading and pressurized conveying of single or multiple ingredients. They use 15 psig convey air to move materials at balanced combination of intermediate line velocities between 2,000-3,000 fpm. Standard units offer capacities up to 80 tons/hr. Conveyors can handle materials that are abrasive and fluidizable and are...

Read More »

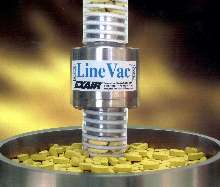

Vacuum Conveyor resists corrosion and contamination.

Air-operated 316SS Line Vac Conveyor converts hose or tube into inline conveying systems for food products, pharmaceuticals, and other bulk materials. Conveyor ejects compressed air to produce vacuum on one end and high-output flow on other. Regulating compressed air pressure provides control of conveying rate. System withstands temperatures to 400Ã-

Read More »

Conveyors are available with vacuum option.

Made-to-order 3200 Series vacuum conveyors have enclosed frame bottom, port for vacuum source, and perforated belt. Offered with widths to 48 in., lengths are available from 4-30 ft in any 1/8 in. increment. Options include choice of flat belt, cleated belt, and center drive models; end and center drive options; and V-Guide belt. Units have belt speeds to 421 fpm and are suited for maintaining...

Read More »

Pneumatic Conveyor provides accurate, continuous operation.

RotoFeedÃ-® incorporates volumetric or gravimetric feeder, provides accuracy of Ã-

Read More »

Application Selection Guide: Choosing the Right Air Compressor

Choosing the right air compressor for your application is essential, but it can feel overwhelming. To learn more about how to make the right choice, read our eBook.

Read More »Vacuum Conveyors handle demanding situations.

C-Series Conveyors are powered by pneumatically driven vacuum pumps, and safely transport 5-6 tons/hr of powders and granules in processing or manufacturing environments. Filter design can trap particles down to 0.3 microns and can be equipped with HEPA filter. Sizes include diameters of 21, 33, and 56 cm. Made of AISI 316L stainless steel, conveyors are suitable for pharmaceutical, food, and...

Read More »

Pneumatic Conveyor handles potential contamination problems.

MiniVac(TM) features individually controlled spray wash ports throughout interior allowing user to clean and sanitize conveyor's interior without external procedures. Side access door permits quick filter cartridge change outs, and clean-in-place rotary valve allows disassembly, cleaning, and reassembly within minutes. Sanitary finish assembly is 304 SS with sealed motors and controls rated for...

Read More »

Material Handling System provides pneumatic conveying.

Using high pressure gas, DensPhase(TM) conveys material from one collection point to single or multiple reception hoppers via enclosed, dust-free process. Constructed of stainless steel, system operates at temperatures up to 836Ã-

Read More »

Vacuum Conveyors satisfy USDA requirements.

Vacuum conveyors, available with diameters of 21 and 56 cm, deliver capacities of up to 5 metric tons per hour. As all integral components fulfill USDA requirements, systems also fulfill US FDA guidelines. Conveyors' modular construction allows them to be adapted to meet users' needs. They are manufactured using ASTM 316L steel and employ filters that trap particles as small as 0.5 Ã-µm....

Read More »

Indexing Conveyor places parts in position pneumatically.

PCF30 and PCF50 conveyors for light part assembly automate part transfer and load/unload procedures. They index their belts into position via air cylinder. Having no motor means they can be used in hazardous environments. Belt widths are available in 150, 200, 300, 400, and 500 mm sizes. Lengths are from 250 mm to 2000 mm. Typical applications include conveyors, slides, grippers, pick and place...

Read More »

Air Lifts use normal shop compressed air.

Aero-Pallets and Aero-Planks utilize Air-Film technology, which allows omni-directional movement and positioning in tight spaces on loads from 500 lbs to 5,000 tons without causing floor damage. Steering and positioning control is provided via products' Guide Wheel designs. Flat deck (as thin as 2 in. height off of ground) slips under loads and provides its own lift with shop compressed air.

Read More »

Increase Workplace Safety, Manage Heavy Loads with Equipment from A-Plus Warehouse

A-Plus Warehouse carries a wide selection of commercial and industrial material handling equipment at affordable prices. Check out the video to learn more.

Read More »