Indexing Conveyor places parts in position pneumatically.

Share:

Press Release Summary:

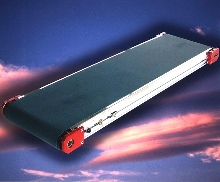

PCF30 and PCF50 conveyors for light part assembly automate part transfer and load/unload procedures. They index their belts into position via air cylinder. Having no motor means they can be used in hazardous environments. Belt widths are available in 150, 200, 300, 400, and 500 mm sizes. Lengths are from 250 mm to 2000 mm. Typical applications include conveyors, slides, grippers, pick and place units, rotary actuators, and modular vacuum components.

Original Press Release:

New Indexing Conveyor For Light Part Assembly

CLEVELAND, OH - May 21, 2002 - ASG, a division of Jergens, Inc., has announced two new conveyors for light part assembly. The conveyors are designed for the automation of part transfer and load/unload procedures. They index their belts into position powered by an air cylinder. Because they are pneumatically-actuated, the conveyors are less expensive than comparable indexing electric motor-driven conveyors.

The new PCF30 and PCF50 models, having no motor, are exceptionally compact and can be used in an explosion-proof environment. Belt widths are available in 150, 200, 300, 400 and 500mm sizes. Lengths are from 250mm to 2000mm.

Typical applications include conveyors, slides, grippers, pick & place units, rotary actuators and modular vacuum components.

ASG is located at 15700 South Waterloo Road, Cleveland, OH 44110-3898.

Telephone (216) 486-6163 Fax: (216)-481-4519. E-mail: asginfo@asg-jergens.com

Web: asg-jergens.com; Inquiries to Bonnie Kitchen.