Dry Grinders produce single micron material.

Press Release Summary:

HSA Dry Grinding Attritors have side discharge screen, and media size of 1-3mm, allowing micron sized products to be generated continuously. Shaft speeds range from 400 to 1800.

Devices provide dry grinding, resulting in extremely fine material. Applications include ceramic powders, glass frits, metal powders, mechanical alloying, metal oxides, fibers and celluose.

Original Press Release:

Union Process Extends High Speed Dry Grinding Attritor Line

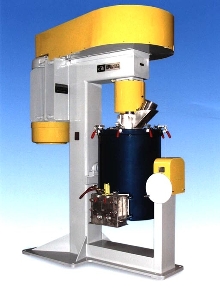

Akron, Ohio...Union Process, inventors and developers of Attritor technology, has expanded its line of high speed dry grinding Attritors with the introduction of several new models in the intermediate range. The HSA Attritor line now is available in a complete range of production models including 10, 15, 20, 30, 50 and 100 as well as the HSA-1 laboratory model.

The patented HSA Attritors feature a unique design concept that includes a new shaft configuration and side discharge screen which allows mills to use smaller media and run at higher speeds, generating a large quantity of micron-sized products continuously.

Generally, the media size used in HSA Attritors is 1-3mm; in some special cases, slightly larger media also has been used. The shaft RPM of the HSA series ranges from 400 to 1800.

Dry Grinding Attritors provide fast, efficient dry grinding, resulting in extremely fine material measured in single microns. Common applications for dry grinding include ceramic powders, glass frits, metal powders, mechanical alloying, metal oxides, fibers and celluose, food products, ferrite, pigments, minerals, coal and coke, graphite, plastics, rubber and chemicals.

Union Process also manufactures a complete line of wet grinding Attritors and small media mills including the QC-Mill(TM) and the DeltaMill(TM).