Ball Mill grinds to sub-micron dimensions.

Press Release Summary:

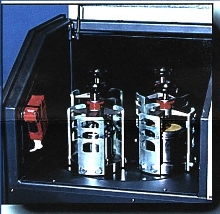

PM 400 Planetary Ball Mill processes up to 8 samples without contamination, grinds material to sub-micron fineness, and has maintenance-free drive. Grinding sets are available in 4 sizes and 6 different materials. Superimposed motion of grinding jars, relative to central wheel, achieves high grinding efficiency. Generated energies by impact and friction of grinding media (beads) permit mixing, grinding and colloidal grinding.

PM 400 Planetary Ball Mill processes up to 8 samples without contamination, grinds material to sub-micron fineness, and has maintenance-free drive. Grinding sets are available in 4 sizes and 6 different materials. Superimposed motion of grinding jars, relative to central wheel, achieves high grinding efficiency. Generated energies by impact and friction of grinding media (beads) permit mixing, grinding and colloidal grinding.Original Press Release:

Retsch Introduces New High-Speed Planetary Ball Mill PM 400

The Planetary Ball Mill PM 400, with its powerful drive, is used for four specialty applications: grinding material to sub-micron fineness, simultaneous processing of up to eight samples without contaminating the sample, industrial environment conditions, and mechanical alloying. The superimposed motion of the grinding jars relative to the central wheel achieves high grinding efficiency. The generated energies by the impact and friction of the grinding media (beads) permit not only the classical mixing and grinding operations, but also other process engineering conditions for colloidal grinding that are pre-requisite to material transformation, such as mechanical alloying. The sturdy floor model with its maintenance-free drive ensures controlled speed even in continuous operation over several work shifts.

Grinding sets are available in four sizes and six different materials. The PM 400 can be used for a wide range of applications in agriculture, construction materials, biology, ceramics, mineralogy, environmental, and materials research.

Retsch is a global company dedicated to providing novel technologies and high quality tools for the sample preparation of solids used in R&D and QA applications as well as small-scale production.