Hard Part Tooling System has insert and tooling options.

Capable of machining steels and alloys hardened to 45-62 Rc levels, ValEDGE(TM) utilizes proprietary ceramic and CBN inserts plus ValTURN(TM) ProGRIP(TM) family of toolholders. System takes advantage of stabilized microstructures and mechanical properties of materials while eliminating or reducing time consuming secondary finishing operations. It also provides tolerance and surface finish control...

Read More »

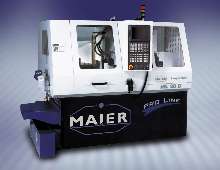

Turning Centers provide complete machining in single setup.

Maier ML ProLine CNC Swiss Turning Centers are available in 5 different series with configurations ranging from 4 axes with up to 11 tools to 11 axes with up to 30 tools. Machines feature 6,000 or 8,000 rpm 5/7.5 hp main spindles, 6,000 or 8,000 rpm 3.5 hp subspindles, and 1,260 ipm rapid traverses within distance of .03937 in. Several models offer simultaneous processing with 2 or 3 tools and...

Read More »

Machining Centers combine turning and grinding.

Suited for wheel or hub type components, Stratos Series CNC multi-tasking centers offer vertical part pick-up and integrated part handling. Models are available with 2, 3, and 4 workstations. Internal grinding system includes arbor with 150 mm aluminum oxide or CBN wheels and 36,000 rpm spindle drive. External grinding system has interchangeable spindle and motor units and 3,000 rpm spindle...

Read More »

Toolroom Lathe features precise, smooth operation.

The Professional, available in gap bed models with 13-21 in. swings and 25-120 in. centers, features cast iron, hardened and ground bedways with triangular webs mounted to cast iron base. Constant Surface Speed DRO is standard on 13 and 15 in. swing models. Equipped with 10 or 15 hp, AC, variable-speed spindle drive, products are available with 3 headstock gear ranges and incorporate...

Read More »

Reflective Tapes and Their Visibility Control Applications

This ebook provides an overview into reflective tapes and their visibility control applications.

Read More »

Combination Brake Lathe services vehicles up to 1 ton.

Combination Rotor and Drum Brake Lathe, model EEBR312A, is suited for high-volume repair shops that recondition brake drums and disc brake rotors. Powered by 1 hp motor mated to variable speed gear box and hand wheel controls, product employs twin cutter tool that reconditions both brake rotor surfaces simultaneously. Features include hardened-chrome spindle, floating shaft, heavy-duty iron...

Read More »

CNC Turning Centers are offered with 2, 3, and 5 axes.

Storm T-series 2-axis turning centers include T2, T4, and T8 models with 1.65, 2.12, and 2.59 in. bar capacities and 7.5, 15, 30 hp spindle motors, respectively. Tri-axial models include T6M and T8M, both with turret-mounted powered tooling and 5 hp tool drive motor. Storm 5-axis sub-spindle single-hit machines add second spindle to Storm T6MS and T8MS turning centers. Equipped with G.E. Fanuc...

Read More »

CNC Turning Center simultaneously machines 1 or 2 parts.

Capable of simultaneous or independent machining, Nakamura-Tome WTW-150 employs twin spindles and 4 turrets. It can turn complex, precision parts completely in one setup. Machining flexibility is provided via independent slides, 13 controlled axes, equal left and right machining, and 48 stations of flexible tooling. Dual FANUC CNCs allow independent programming of each spindle, while polygonal...

Read More »Gang Tool Lathe offers small parts turning.

Prodigy GT-27 Single Spindle Lathe features polymer composite base that resists oxidants, thermal distortion, and vibration. Precision is achieved through incorporation of non-heat generating collet closers, absence of turret, and standard third indexing axis. Since lathe can index in 1Ã-

Read More »

CNC Turning Center incorporates overhead part unloader.

With 6.500 in. through-hole capacity, 4-axis turning center features two 12-station, interference-free turrets and flexible tooling systems. Cast iron base and spindle drive system make product suited for heavy metal removal and high-precession turning applications.

Read More »

Turning Center suits mid- to high-volume production.

Model E 320 offers turning, boring, milling, and tapping in one setup. Machine can be configured with 1 or 2 spindles, C axis, live tools, and Y axis. It features max cutting length of 23.62 in., cutting diameter of 12.6 in., and 27.55 in. swing. Main components are assembled on solid base incorporating polygonal ribbed working platform, which is supported on 45Ã-

Read More »

SRG Global Coatings Enhance Surface Durability, Efficiency, Design Flexibility

SRG Global's automotive coatings enhance the structural integrity of the finished part while also improving vehicle efficiency. Check out our video to learn more.

Read More »