Horizontal Machining Center has 40 hp, 6,000 rpm spindle.

Able to machine steel without compromising rigidity, FH-SX incorporates spindle with double driving force on Y axis, with ballscrew and motor on each side. Column supports spindle's cutting power and maintains accuracy in hard, ferrous materials, and included software has automatic compensation to protect against thermal growth in ballscrew. Offered in 550 or 630 mm pallet sizes, machine has...

Read More »Custom Machining Centers provide multi-axis solutions.

FlexCenter FC350, FC450, and FC630 feature respective work cubes of 14, 18, and 25 in. and can be supplied with horizontal or vertical spindle and turret or basic platen. Model FC350 can be configured with 40-taper or HSK63 tool interface; FC450 with 40- or 50-taper, HSK50, or 63- or 100-tool interface; and FC630 with 50-taper, HSK63, or HSK100 tool interface. Machines feature centralized...

Read More »

CNC Bar Machine has heavy-duty counter spindle.

Capable of simultaneous 3-tool cutting, C65 features Polygon Generating Capability, 2 Y-axes for turrets, and guide-ways for turrets with slides based on plate-type slide system. Turret slides and counter-spindle slide offer 1 g acceleration rate and rapid traverse rates of 75 and 150 fpm. With 1 5/8 or 2Ã-½ in. bar capacities, machine offers respective max spindle speeds of 6,300 and 5,000...

Read More »

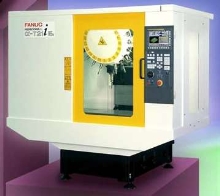

Vertical Machining Center employs Fanuc 31i-A5 CNC.

With feedrates to 1,181 ipm and rapid traverses to 2,125 ipm, 30-taper E Series RoboDrill is suited for drilling and tapping, milling, boring, and deburring. It comes with 14- or 21-station tool changer and choice of 5/7.5 hp, 10,000 rpm or 2/5 hp, 24,000 rpm spindle. Featuring thermal compensation and HRV control, unit delivers positioning accuracy of 0.0002 in. and repeatability of Ã-

Read More »

System Selection: Smart Hardware Choices Enable a Cascade of Value

This white paper outlines six questions to help OEMs and ISVs select the right hardware design to best support their purpose-driven application and product.

Read More »

Machining Center offers multi-tasking operation.

Integrex 100-IIIST features 6,000 rpm max turning spindle speed with 6 in. chuck and milling spindle with 12,000 rpm max speed. Second spindle eliminates work-in-process; parts are completed in one setup on one machine. Linear guides are provided on X, Y, and Z axes, with rapid traverse speeds of 1,181, 1,024, and 1,299 ipm, respectively. Machine includes automatic tool changer with 20-tool...

Read More »

High-Speed Machining Centers include tool storage tower.

ProdMod HSM 600U and HSM 800 use storage tower for compact positioning of scalable tools. Tower is constructed with circular suspended shelf offering 120, 170, and 220 tool positions. With double tool handling, changeover times are less than 2 sec and chip-to-chip time is 5 sec. HSM 800 machines heavy workpieces up to 2,200 lb and offers unmanned operation, while HSM 600U provides simultaneous...

Read More »Vertical Machining Center suits hard-milling applications.

Featuring traverse and cutting feed rates of 1,574 ipm on all axes, E33 mills graphite and steel with minimal vibration. It comes with SGI.4 ULTRA 3D software and Pro.5 controller in addition to HSK 40,000 rpm spindle and 30-tool automatic tool changer. Standard work table is 35.5 x 19.7 in., and work load capacity is 1,102 lb. In addition to 25.6 in. X axis and 17.7 in. Y and Z axes, machine...

Read More »

Machining Centers feature cast iron construction.

Suited for milling large parts and molds in variety of materials, Model RH33 offers XYZ travel of 78 x 33 x 28 in. while Model RH35 offers travel of 120 x 35 x 30 in. Both machines feature open frame construction and are available with various accessories including automatic tool changers, chip guards, and No. 40 or 50 spindle. Base to saddles are supported by several box ways to maintain...

Read More »

Production Cell is suited for high-speed operations.

Suited for unattended machining, Fanuc RoboCell(TM) combines multi-axis robotic loading and unloading with ability to stage enough small parts for entire shift. System, comprised of Fanuc 30-taper RoboDrill E Series VMC and Fanuc 5- or 6-axis robot, is suited for drilling, tapping, and milling. It features 2,125 ipm traverses rates; 0.9 sec tool changes; and 6 sec load/unload times. Included...

Read More »

Micro-Tooling CNC Machine offers remote monitoring/control.

Constructed with solid granite machining table, miniRaptor(TM) utilizes 60,000 rpm spindle with 0.125 in. collet, has 51 x 51 in. footprint, and provides 20 x 20 x 8 in. working envelope with room for fixturing and batch machining of small parts. Unit incorporates 3-Tool Automatic Tool Management System(TM), and WindowsÃ-®-based control software. Along with 15 in. monitor, unit offers...

Read More »

TPA Motion Introduces New Curved Linear Rail Guides: the CR40 Series

For the ultimate in precision open and closed loop guided motion systems, TPA Motion is the leader in curved rail, liner guides. We specialize in engineering excellence, with products that exhibit an elevated level of precision, delivering robust performance, even under the most challenging conditions. See our video to learn more.

Read More »