Pick, Place, and Press System applies press-fit connectors.

Rated for 8 tons, in-line Automatic Pick, Place and Press (AP3) Machine incorporates press force monitor that tracks force exerted for each component pressed onto board. Capable of processing components up to 1.25 x 1.25 x 12 in. long, unit accepts PCBs up to 30 in. long by 18 in. wide. Product utilizes downward looking camera for locating PCBs, upward looking camera that monitors/inspects...

Read More »

PC Board Assembly System features modular design.

Genesis PCB material handling platform is built with rigid extrusion profiles. Configurable voltage settings range from 110-220 Vac, 50 or 60 Hz. CE-compliant system includes zinc-plated metric hardware, ESD safe belts with dual stepper motors, and standard SMEMA interfaces.

Read More »

Modular Framing System is assembled without welding.

Series 40 aluminum profile system has 40 x 40 to 120 x 240 mm base sections, 90 cross sections, and wide selection of connector accessories, including corner blocks, universal angle brackets, hinges, base plates, and gussets. Components can be used to build light machine frames, enclosures, guarding, work stations, railings, stairs, and platforms. Complex, precision assemblies can be built using...

Read More »

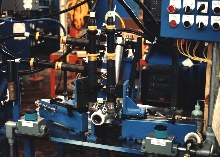

Stent Crimping Equipment continuously monitors crimp diameter.

Series 1000 integrates process-monitoring features along with automation to suit manufacturing environments. PC operated, software driven system allows user to create file structures for different size combinations, which can be recalled. Load cell provides process monitor by showing force applied to activation arms while utilizing mechanical stops. Stent Crimping Equipment includes vision...

Read More »

Avoid Pressure Equipment Failure

This eBook gives a guide on how to prevent pressure equipment failure.

Read More »

Manufacturing Systems feature PC-based machine control.

Flexsys(TM) automated manufacturing systems accommodate multiple process and assembly operations on one automated platform, and can be scaled up or reconfigured. Available models include Flexsys(TM) 1000 for semi-automated production and Flexsys(TM) 2000 for fully automated assembly and processing. Flexsys(TM) 3000 high-speed die bonder provides epoxy stamping to 50 microns, and Flexsys(TM) 4000...

Read More »

Die-Feeding System eliminates secondary operations.

Portable PEMSERTER(R) Die-Feeding System installs self-clinching nuts, studs, and standoffs in workpieces during stamping processes. System utilizes multi-pin, twist-lock connectors, and includes touch-screen and online library of fault/help screens. Only standard 110 V receptacle and shop air are required for operation. System can be configured for multiple or single insertions, generally...

Read More »

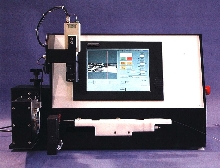

Inspection System verifies glue dot placement on PCBs.

GlueScan(TM) AOI uses Windows interface integrated with automatic table and image-processing unit to provide 100% inspection of adhesive placement on PCBs after stenciling, dispensing, or stamping. It is available in 2 versions: in-line conveyor module where boards are shuttled in, automatically aligned, and checked for accuracy with Pass or Fail inspection, or as off-line desktop module where...

Read More »Assembly Platform maximizes production efficiency.

Linear motor driven CHADIQh-1 odd-form, final assembly and photonics assembly platform has footprint of less than 1 meter. It is capable of handling virtually all off-form through-hole and surface mount applications along with fully automatic device assembly applications.

Read More »

Assembly System reduces damaged materials and reworks.

Fully automated tube nut assembly system simultaneously operates 4 slide mounted electronic nut runners that travel on and off tube nuts on command from computer, which controls operation and records torquing data to disc. System uses clutching socket end effector designed to travel straight on and straight off from side of any nut eliminating tedious task of positioning tool on tube nut.

Read More »

Eliminate Expensive Repairs with the Hot-Shot Pipe Thawing Machine

The new Hot Shot Pipe Thawing Machine delivers an innovative and highly effective approach to thawing frozen pipes. Easy to use and versatile, it is loaded with robust features that further suit it to many challenging environments. To learn all about it, see our video.

Read More »