Stud Bumper handles 12 in. wafers in one pass.

WaferPRO plus single-pass stud bumper bonds 22 bumps/sec, depending on bump type, size, and pitch. It offers +5 Ã-µm positional accuracy at 3 sigma and can bump down to 65 Ã-µm. Various manual chucks and fully automatic wafer handling options are available. WaferPRO plus kit, which includes hardware, specialized servo code, and motion profiles, provides upgrade path for existing WaferPRO...

Read More »

Machine aids in prototype/testing applications.

Measuring 8 in. wide with dimensionally warranted precision modules in 18 in. increments, Agileslim PL is available in 3 configurations: carrousel, vertical, or over and under. It utilizes servo-controlled or cam controlled motion for intermittent or continuous movement. Unit can be expanded, contracted, or modified, and is available with 2 or 3 in. precision links. It serves as production...

Read More »

Placement Machine offers speeds of up to 48,000 cph.

Model 4797R HSP measures 3,100 x 2,155 mm and can handle boards up to 610 mm x 460 mm. It includes twelve 5-spindle, direct-drive placement heads and UCT53 software for offline programming. Three-sigma accuracy is 0.08 mm for MELFs and small chips, and 0.05 mm for leaded components. Machine accepts up to 72 unique components on standard 8 mm tape feeders, or 96 unique components with dual-track...

Read More »Press Center assembles complex backplanes.

Accommodating large and complex backplanes, modular Model EPC III rapidly fits PCBs with power terminals, HM connectors, ERmet ZD, and DIN strips. Connectors up to 180 mm in length are fed from packaging trays to transport conveyors. Robot makes it possible to remove and feed special connectors up to 250 mm long from any packaging. With pressing force of 80 kN, machine handles 1,200 x 600 mm PCBs...

Read More »

6 Reasons to Consider Hydroforming over Traditional Metal Stamping

To learn more about the functions of the hydroforming process, the key differences from other processes, and why it is preferable over other stamping options, download this eBook now.

Read More »

Tray Feeder handles range of semiconductor component trays.

Model TF30 Automated Tray Feeder processes devices in and out of JEDEC and semiconductor-specific matrix trays during programming. Self-adjusting feature allows it to change tray configurations in seconds without need for operator adjustments. Batch Plus(TM) process allows component replenishment to feeder while host machine continues to program and process components. Model TF30 is compatible...

Read More »

Placement Machine offers up-front configurability.

Built on Vantis platform, AdVantis(TM) scalable solution is suited for low-margin assembly applications. Basic in its standard format, machine features single-beam positioning system and is available with various options to make it readily configurable to specific applications. Product is suited for high-mix and high-volume manufacturers who need no more than it takes to perform certain tasks but...

Read More »

Dip-Flux Feeder facilitates flip chip assembly.

Dip-Flux Feeder picks up component from waffle tray, stick feeder, or tape feeder, then dips component, leads, or BGA balls into rotating flux bath. It then places component or flip chip onto board or substrate. Fixed squeegee in rotating flux bath ensures constant flux wave height. Laser sensors detect approaching components and halt squeegee rotation for duration of dipping process. Feeder is...

Read More »

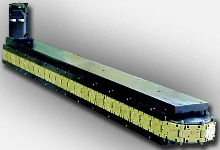

Linear Assembly System is cam-driven.

Weiss LS uses barrel-cam drive to position modular pallets around system and into and between locking stations on belt conveyors. Station-to-station transfer time is as low as 0.4 sec, and transfer times are as fast as 4.4 fps. Pallet speed is controlled by integrated frequency inverter with PLC control. Modular in design, system includes 3-position, single-locking station and 7-position,...

Read More »

Piston Ring Assembly System suits large diesel pistons.

Fully automatic system, with gantry pick-and-place, employs single-step loading of oil control ring and coil spring. System handles complete assemblies in one, 3-stop operation. During ringing process, piston does not touch any reference surfaces and no machine part touches piston dome. Expanding cone maintains full contact with ID of ring and allows rings to be opened gradually and consistently....

Read More »Assembly System facilitates final assembly and box build.

Pallet-based Dynamic Assembly System (DAS) incorporates factory concept platform with standard modules and operational/quality software. System supports concurrent engineering, fast capacity increases, or changes of line layouts. Able to cope with customer order initiated assembly and less than 24 hr production lead time, product achieves balancing of production mix and volume by utilizing pallet...

Read More »

Triad's Next-Gen Power Supplies Offer Increased Reliability and Reduced Noise Performance

Triad Magnetics, an established leader in power supply design and manufacturing, is proud to announce their next generation WAU AC and WDU DC Series of power supplies. These linear wall plug-ins offer minimum noise performance without sacrificing reliability or life. See our video to learn more.

Read More »