Multifunction Machine Tools perform milling and turning.

EMCOTURN 420MC has 2 main spindles, 2 counter spindles, and 2 tool turrets. It handles simultaneous machining of two parts without interruption or collisions. Digital drives produce performance in both main spindle and X and Z axes. HYPERTURN 665MC combines 4 axis turning capability with Y and B axes, adjustable milling spindle, cross-roller linear guides, and easily accessible tool turrets. It...

Read More »

Modular Processing Systems offer turnkey solution.

Modular Processing Systems, for material processing, are factory-engineered and pre-assembled, minimizing on-site labor for erection, custom fitting, and unforseen factors. Systems include structure and individual equipment as required including Multi-AspiratorÃ-®, cyclones, fans, filters, airlocks, spouting, and automation. Systems are suitable for industries such as grain and milling,...

Read More »

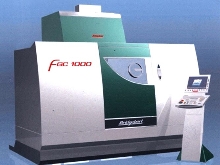

Milling Machine features fixed bed design.

HS-324 features dual-opposed spindle milling head with 2 separate spindles: 6000 rpm, 20 hp conventionally driven unit providing low end torque for roughing; and 30,000 rpm, 10 hp electrospindle for high speed finishing. Five axis capabilities are achieved by combining swiveling vertical spindle with rotary table built-in to stationary table surface. Rotary table is 40 in. dia and runs at 80 rpm...

Read More »

Horizontal Milling Machine can produce two parts at a time.

TWIN 800 Milling Machine has 2 horizontal spindles, which can be operated synchronously or independently. Two permanent magnet spindle motors provide full 37 hp from 4500 rpm through 18,000 rpm, and are equipped with anti-collision sensors. Torque motor technology drives rotary tables at 120 rpm and tilting platform at 50 rpm. Linear axis feed rates are 1100 ipm. Twin independent tool changers...

Read More »

Elastomer Shlastomer, Right? Selecting the Right Elastomer for Your Sealing Boots and Fasteners

Different elastomer formulations affect your parts' physical properties, functions, and service life. Therefore, it's important to test a few different elastomers, when assembling your product, to determine the best one for your needs.

Read More »

Vertical Milling Machine provides both roughing and finishing.

Model THS traveling column milling machine features dual opposed spindle milling head. CNC controlled rotary axis positions 37 hp, 5000 rpm, 50 taper spindle for roughing; and 16 hp, 28,000 rpm, HSK 50 taper spindle for finishing. Five sided, 5-axis machining capabilities are achieved by combining head rotation with built-in 49 x 39 in., 11,000 lb capacity rotary table. Machine features axis feed...

Read More »

Milling System machines cast and malleable iron components.

M750 Milling System, with silicon-nitride ceramic and coated-carbide grades, offers 2 milling cutter bodies in 6 diameters from 3.94 to 12.40 in. for 45Ã-

Read More »

Boring Mill features 5.3 in. diameter spindle.

HBA-135P-R5 Planer Type 5 in. CNC Horizontal Boring Mill is equipped with Nitride hardened and precision lapped spindle and 60 hp main motor. Rotary table size is 71 x 80 in., with max load capacity of 26,400 lbs. Travels for head stock vertical, table cross, and table length are 91, 120 and 55 in. respectively; spindle travel is 28 in. Spindle speeds range from 5 to 2,500 ipm. Machine includes...

Read More »

CNC Machine Tools have GE Fanuc controls.

Advanced family includes vertical machining centers and grinders. XV-Series 18-hp VMC has up to 1100 ipm rapid traverse rates on X and Y axes and rigid tapping standard. Model 4024 XV has 40 x 24 x 24 in. work envelope, making it suitable for use on 2 ft molds. XP-Series VMCs have traverse rates as high as 1,690 ipm, profile acceleration rates of 6m/secÃ-², and dynamic thermal compensation....

Read More »

Horizontal Boring Mill has 590 ipm traverse rates.

Model PC 50 table-type boring mill measures 63 x 49 in., and offers cast iron frame and box ways. Positioning accuracy is .0004 in. and repeatability is .0002 in. Unit's 60 hp, two-speed headstock houses flexible bar-type spindle, which operates at speeds to 4,000 rpm. Contouring rotary table has 25,000 lb load limit, and handles parts with X/Y/W/Z travels of 2500/2100/800/1575 mm respectively....

Read More »

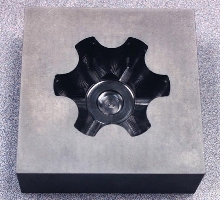

Jig Mills offer cutting capability of 90 HRC.

YBM Jig Mills feature self-adjusting preload spindle and thermal distortion stabilizing system. Combination of diamond coated cutters and Climb Cut Method results in 3D profile machining of cemented carbide 90 HRC. Applications include forming, drawing, and extrusion dies for automotive, aerospace, and consumer products industries.

Read More »

Increase Workplace Safety, Manage Heavy Loads with Equipment from A-Plus Warehouse

A-Plus Warehouse carries a wide selection of commercial and industrial material handling equipment at affordable prices. Check out the video to learn more.

Read More »