Modular Processing Systems offer turnkey solution.

Press Release Summary:

Modular Processing Systems, for material processing, are factory-engineered and pre-assembled, minimizing on-site labor for erection, custom fitting, and unforseen factors. Systems include structure and individual equipment as required including Multi-Aspirator®, cyclones, fans, filters, airlocks, spouting, and automation. Systems are suitable for industries such as grain and milling, chemical, plastics, foundries, and mining.

Modular Processing Systems, for material processing, are factory-engineered and pre-assembled, minimizing on-site labor for erection, custom fitting, and unforseen factors. Systems include structure and individual equipment as required including Multi-Aspirator®, cyclones, fans, filters, airlocks, spouting, and automation. Systems are suitable for industries such as grain and milling, chemical, plastics, foundries, and mining.Original Press Release:

Kice Modular Processing Systems Offer Turnkey Solution

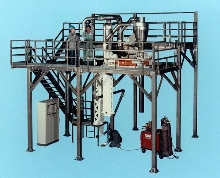

Modular Processing Systems from Kice Industries, Inc. offer a turnkey solution to material processing for a variety of industries including grain and milling, chemical, plastics, foundries, mining and more. Modular Processing Systems are factory-engineered and pre-assembled, all that is needed is power and space.

Using Modular Processing Systems can save 50%-90% on building requirements and costs by minimizing on-site labor for erection, custom fitting and unforeseen factors. Systems include the structure and individual equipment as required; such as the Kice Multi-Aspirator®, cyclones, fans, filters, airlocks, spouting and automation. Existing plant equipment can also be integrated into a more compact, easier-to-operate system.

Modular Processing Systems offer layout, design, build and automation from a single source with over 50 years of experience. Heavy duty Kice equipment components and Kice Automation are combined for maximum performance.

Kice Industries, Inc., 5500 N. Mill Heights Drive, Wichita, KS 67219, (316) 744-7151, FAX (316) 744-7355, www.kice.com.