VMC suits mixed volume operations.

Featuring 50 x 24 x 25.2 in. work envelope and 52 x 22 in. work surface, D1250 vertical machining center offers traverse rates of 1,181 ipm (X-,Y-, and Z-axis) mean accelerated machine cycle times. Automatic tool changer with bi-directional selection mode offers 22-tool capacity and 5.5 sec station-to-station index time. Belt-driven heavy-duty cartridge-style headstock features 20 hp ac...

Read More »

Wire-Cut EDMs offer high-precision manufacturing.

Vertex 2, 2F, 3, and 3F models feature IPG-V generator, which delivers fine spark gap for optimal part geometry and surface finishes down to 0.05 Ã-µm Ra with no white layer in continuous operation. Vertex 2F is equipped with Agievision 5 control based on Windows XP platform and powered by dual Pentium M processors, 40 GB hard drive, and 512 MB RAM, which provides 3D graphics, real-time...

Read More »

VMC suits mixed volume, short run/high volume applications.

With work envelope of 30 x 15.98 x 20 in. and table work surface of 36.02 x 14.17 in., D 760 vertical machining center offers rapid traverse rates of 1,181 imp (X- and K-axis) and 787 imp (Z-axis) mean accelerated machine cycle times. Automatic tool changer with bi-directional selection mode offers 22-tool capacity, and 5.5 sec station-to-station index time. Poly-V belt-driven heavy-duty...

Read More »New Hampshire Stamping Adds to its Capabilities

Founded in 1991, New Hampshire Stamping Corporation has grown to become a leader in the vast array of metal stamping technologies. With over a decade of experience, we have the knowledge and versatility to meet almost any stamping challenge. NH Stamping has been providing you with quality metal stamping and engineering since 1991. With the purchase in January 2006 of ROBOCUT a-1 iC we now can...

Read More »

How to Choose the Right Label for Your Application

This ebook discusses factors to consider when choosing the optimal label for your application.

Read More »EDM Machines/VMCs suit surface finishing applications.

Wire EDM Model FA10S features programmable flushing system, fine finish power supply, and non-isolated workpiece table. Sinker EDM Model EA12V includes multi-position work tank, which allows operator to set up while circulating dielectric fluid. ESPER II software offers multiple programs for measuring, power settings for burning, and orbital data for finishing. High-speed Model HC-658 VMC...

Read More »

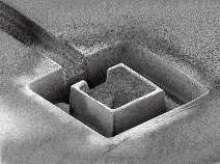

Micro-Machining Service targets medical device market.

Offering sub-micron tolerances, UV Laser Micro-Machining Service processes polymers and plastics, ceramics, glass, metals, semiconductor materials, diamond and precious metals at 355, 351, 308, 266, 248, 193, and 157 nm wavelengths. Laser systems are equipped with air bearing motion stages to ensure precision and accuracy. Typical applications include micro-fluidics, sensors, nozzles,...

Read More »

Polycarbonate Material suits rapid prototyping applications.

Type PC-ISO meets ISO 10993-1 and USP Class VI standards and is suited for food, pharmaceutical, and medical equipment modeling. It can be sterilized using gamma radiation or ethylene oxide method. Available in translucent and white, product is suited for T-Class rapid prototyping systems. Components built from translucent PC-ISO allow viewing of solid or liquid material flow. Model-layer...

Read More »

Custom Components suit hydraulic/pneumatic equipment.

Custom-manufactured to user specification, cylindrical components feature complex cross and through holes, slots, flanges, threads, and milled surfaces. Parts range in diameter from .25-2Ã-¾ in. and length from Ã-½ in. to 3 ft. They are accurate to .0002 in. for circularity, cylindricality, concentricity, and runout accuracy and are repeatable to within .00015 in. Materials include steel,...

Read More »RTCP Function is suitable for 5-axis machining.

RTCP (Rotation Tool Center Point) Function maintains rotary axes at constant angle between tool and surface to be machined. Machine also allows OEMs to set up function based on mechanical properties of users' machines. RTCP function manages all irregularly shaped offsets automatically, and keeps tool in contact with programmed point. It uses contact point as reference point in all calculations,...

Read More »

Multi-Axis Machining Center has highest accuracy available.

Model HU50-5AX Trunnion Table 5-axis CNC machining center holds 0.00012 in. true position (ISO 230-2) through all linear axes and 0.001Ã-

Read More »

TPA Motion Introduces New Curved Linear Rail Guides: the CR40 Series

For the ultimate in precision open and closed loop guided motion systems, TPA Motion is the leader in curved rail, liner guides. We specialize in engineering excellence, with products that exhibit an elevated level of precision, delivering robust performance, even under the most challenging conditions. See our video to learn more.

Read More »