Vertical Machining Centers suit large mold manufacturing.

Share:

Press Release Summary:

High-speed Models V99 and V99L help minimize benchwork and post-production polishing on large die and mold work. With 70.8 x 39.4 in. worktable, Model V99 features X, Y, Z axes of 59 x 39.4 x 31.5 in., while Model V99L provides X, Y, Z axes of 78.7 x 39.4 x 31.5 in. with 90.5 x 39.4 in. worktable. Machines offer rapid traverse and cutting feedrates of 787 ipm and come with #40 taper 20,000 rpm or #50 taper 12,000 rpm spindle. Both are equipped with Professional 5 Control utilizing Windows CE(TM).

Original Press Release:

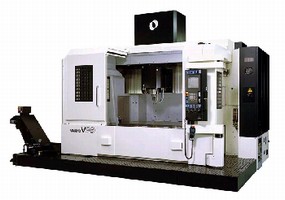

Makino Introduces the V99 and V99L High-speed VMC for Large Mold Manufacturing

Makino Introduces the V99 and V99L High-speed VMC for Large Mold Manufacturing

Designed for high-speed, large mold manufacturing

AUBURN HILLS, MI - November 2006 - Makino's V99 and V99L vertical machining centers (VMC) are engineered to provide superb accuracy and high-speed performance previously unobtainable with large die/mold milling machines. These capabilities of the V99 and V99L help eliminate or reduce benchwork and post-production polishing on large die and mold work.

"The V99 and V99L provide the speed, accuracy and stability needed to tackle large molds and dies effectively," says Bill Howard, VMC product manager at Makino. "Most importantly, both come with Makino's unmatched expertise in the die/mold manufacturing market."

The V99 has an X-, Y-, and Z- axes of 59 x 39.4 x 31.5 inches (1,500 x 1,000 x 800 mm), with rapid traverse and cutting federates of 787 IPM (20,000 mm/min.). A large worktable of 70.8 x 39.4 inches (1,800 x 1,000 mm) accepts a maximum workpiece of 70.8 x 39.4 x 25.6 inches (1,800 x 1,000 x 650 mm) weighing up to 8,800 pounds (4,000 kg). The V99 is a rugged 50,692-pound (23,000 kg) machine that is 15.4 feet wide x 13.5 feet deep x 11.5 feet tall (4,700 x 4,100 x 3,500 mm)

The V99L has an X-, Y-, and Z- axes of 78.7 x 39.4 x 31.5 inches (2,000 x 1,000 x 800 mm), with rapid traverse and cutting federates of 787 IPM (20,000 mm/min.). A large worktable of 90.5 x 39.4 inches (2,300 x 1,000 mm) accepts a maximum workpiece of 90.5 x 39.4 x 25.6 inches (2,300 x 1,000 x 650 mm) weighing up to 8,800 pounds (4,000 kg). The V99L is a rugged 57,304-pound (26,000 kg) machine that is 17.1 feet wide x 13.5 feet deep x 11.5 feet tall (5,200 x 4,100 x 3,500 mm)

Both machines come with a #40 taper 20,000-RPM or a #50 taper 12,000-RPM spindle as standard equipment. This accommodates a maximum tool size of 4.7 inches (120 mm) in diameter by 11.8 inches (120 mm) in length and weighing 17.6 pounds (8 kg) on the #40 taper - or 5.7 inches (145 mm) in diameter by 15.7 inches (400 mm) in length and weighing 44 pounds (20 kg) on the #50 taper. An HSK A100, 18,000 RPM spindle is optional, as is five-axis capability.

The V99 and the V99L incorporate 0.05 micron scale feedback on all axes providing a positioning accuracy of ±0.000060 inches (±0.0015 mm) and repeatability of ± 0.000040 inches (±0.001 mm) for superb positioning and contouring accuracy for continuous machining of large workpieces.

"When you're dealing with large workpieces, stiffness and rigidity can make a huge impact," Howard continues. "Finishing times can last several days, the workpieces can be very heavy and hard to set up, and eliminating steps like stress relieving or having the ability to hard mill can save huge amounts of time and money. It takes a serious machine and serious know-how to machine large molds efficiently. That's what the V99 and Makino's application engineers provide."

Features and Benefits

High-efficiency machining requires a system for quick, efficient evacuation of chips. A highly reliable, quick, efficient work zone chip removal system is standard with both the V99 and the V99L, with other system expansions available as options.

Eighteen outlet holes are provided below the table of the machines to reliably catch chips, regardless of the table position. Four built-in hinge-type chip conveyors evacuate chips at high speed toward the front of the machine.

The bed and column are protected by covers to prevent any freshly cut hot chips and coolant from direct contact with their cast-iron surfaces. The areas around the column and the bed as well as underneath the bed are insulated to eliminate thermal changes in the cast-iron machine structure caused by variation in the shop temperature.

Thorough machine usage studies by Makino led to the ergonomic design of the V99 and V99L, providing excellent access to the worktable from three sides of the machine. The automatic tool changer (ATC) magazine door features an extra large opening for the comfortable changing of heavy tools. A 30-tool ATC is standard equipment, with options available for 30, 40, 60 and 80 tools - depending upon the spindle configuration.

Both the V99 and V99L are equipped with the Makino Professional 5 Control utilizing Windows CE(TM) to provide a stable, secure, platform with reliable performance on the NC side, while providing an operator friendly graphical user interface (GUI). This latest generation machine tool control offer large, color, touch sensitive, on-screen, menu driven applications.

Icons provide "hot links" and quick access to critical information that may be required by the operator. In addition, the new control platform provides all of the functions typical of a PC (cut, paste, copy, find, replace, etc.) that are rarely available on a machine tool control. Advanced data management technology and Makino's proprietary, next generation Super Geometric Intelligence (SGI.4) servo control deliver the lowest cycle times available.

Makino is a global provider of advanced machining technology and application support, where new thinking takes shape for the metalcutting and die/mold industries. Makino manufacturing and service centers are located in the United States, Japan, Germany, Singapore, Italy, France, Korea, Taiwan, Turkey, China, Mexico, Brazil and India, and are supported by a worldwide distributor network. For more information call 1.800.552.3288, or visit www.makino.com