Toyoda's FH-S Series' High-Spindle Speeds Achieve 30 Percent Faster Cycle Times

Arlington Heights, IL - Toyoda Machinery's FH-S Series horizontal machining center increases throughput by pairing high spindle speeds with faster non-cutting operations, resulting in 30 percent faster cycle times. The FH450-S is a fast and powerful 40-taper HMC, and has been designed for quick acceleration and deceleration. It has a significantly larger work envelope than comparable machines,...

Read More »Sharp CNC Displays the Drill and Tap Center MDT-510 at IMTS 2006

Torrance, CA - Sharp CNC will display their newest product line CNC Drill and Tap Center MDT-510 at the IMTS show in Booth A-8474. The reliable Fanuc control makes the ST-10 easy to operate. With special Sharp CNC features like word-processor editing, one-button features, multi-function jog handle, and Manual Guide Programming, you'll discover that the Fanuc control is completely user-friendly....

Read More »

Machining Center features max spindle speed of 12,000 rpm.

Suited for use in transfer lines or as stand-alone machine, ZH4000 Horizontal Machining Center allows for multiple machining operations using variety of workpieces. Machine is equipped with 25/15 hp spindle drive motor and 15.7 x 15.7 in. table. It features X, Y, Z axis travels of 25 x 22 x 22 in., all with rapid traverse rates of 2,362 in./min. Y and Z axes drives are centered on column.

Read More »Maintenance Technologies Exhibits Retrofit Package for Cincinnati Arrow VMCs with Control Techniques CNCs in Booth A-8218 at IMTS 2006

Chicago, IL, September, 6, 2006 - Maintenance Technologies demonstrates their MachineMate-®-based retrofit CNC package for Cincinnati Arrow 500 and 750 vertical machining centers equipped with the obsolete Control Techniques CNC in Booth A-8218 as part of the MAG Industrial Automation Systems exhibit at IMTS 2006. Designed as an all-inclusive control replacement package, the new retrofit...

Read More »

Selecting the Right Materials for Your Metal Stamping Project

Learn about metals and their characteristics to help you choose the right option for your unique application.

Read More »

Machining Centers feature max spindle speed of 8,000 rpm.

Suited for use as stand-alone machines, 50-taper ZV5500 and 40-taper ZV5400 VMCs provide X, Y, Z travels of 44 x 22 x 22 in., with rapid traverse rates of 2,362 ipm in X and Y axes and 1,654 ipm in Z axis. Table size is 51.7 x 24.4 in. Model ZV5500 is equipped with 35/30 hp spindle drive motor, while Model ZV5400 features 25/20 hp motor.

Read More »

Mitsubishi Demos Technology that Keeps Die/Mold Makers Globally Competitive

The domestic die/mold industry is now facing a global market, making this traditionally competitive business even tougher. Die/mold makers must focus on targeting niche markets and developing specialized products, materials, processes and customer knowledge in order to survive in today's market - and compete on value instead of cost. The booth's die/mold area will feature automated combinations...

Read More »

Machining Center offers max spindle speed of 12,000 rpm.

Equipped with 20/15 hp spindle drive motor and 20.5 x 18.9 in. table, Model ZV4000 VMC allows for multiple machining operations using variety of workpieces. Machine offers X, Y, Z travels of 23.6 x 17.7 x 17.7 in., all with rapid traverse rates of 1,969 ipm. Designed with Y-axis drive located at center of machine, Model ZV4000 performs as stand-alone unit or as part of flexible machining cell.

Read More »

Mitsubishi Delivers the Exacting Tolerances Demanded in the Aerospace Industry

The aerospace industry operates in an environment of constant change. When it comes to quality control, there's zero tolerance for error. Shops that can quickly and cost-efficiently deliver parts with exacting tolerances are positioned for excellence in the aerospace industry. The booth's aerospace area will feature technology paired for performance on complex parts in extremely hard materials...

Read More »

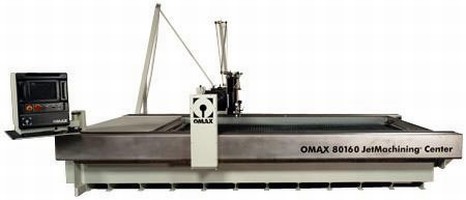

OMAX-® to Showcase New Solutions for Abrasive Waterjet Machining at IMTS 2006

Company's precision waterjet machining centers offer unmatched speed, accuracy and versatility Kent, Washington, June 21, 2006 - OMAXÃ-® Corporation, the pioneer of high-quality, precision waterjet machining systems, will feature two of its premiere JetMachiningÃ-® Centers, the 2626|xp and the 80160, at IMTS 2006. OMAX's innovative machines will be displayed in booth B-6235 in the...

Read More »Makino V22 Compact Vertical Machining Center

Excellent for high accuracy, small part machining MASON, OH- January 2006- Makino's V22 vertical machining center is designed for small part, high-accuracy machining. The V22 offers a 40,000-RPM spindle with superior finishing abilities, ideal for intricate work. The V22 delivers superior performance in a footprint that is only two-thirds that of the popular Makino V33. It is ideal for precision...

Read More »

How SpinSelect Can Save You Time and Money

Thanks to the unique SpinSelect™ Multi-Pocket selectable quick change tool holder, it's time to rethink the range, complexity and volume of parts that your lathe can produce. Our Spin-Select™ tool was created to increase productivity and consistency by decreasing downtime associated with lathe cutting tool and insert setups or changeovers. This product is a game-changer for the industry and we're pleased to show you why.

Read More »