Batson Expands Nonwovens Machinery Line

Greenville, SC: In a move to expand their services to the nonwoven industry, Batson Group, Inc., recently announced their newly formed sales relationship with Fleissner, GmbH. Batson through their sales association with American Truetzschler, will now market, in the United States and Canada, Fleissner's spunlace and chemical bonding systems as well as their belt and perforated drum ovens....

Read More »HDK Industries Announces the Startup of a New Carding Line

March 18, 2009 (Rogersville, TN): HDK Industries announces the commissioning of a manufacturing line at its Rogersville, TN production facility. The line is engineered with the highest performance carding equipment available and will allow HDK to expand its offering of products over a wider range of basis weights. The design of the line was based on extensive market and technology research and...

Read More »Elsner Recently Shipped its' First Model GWR-760 High Speed Fully Automatic Wallcoverings Rewinder

Elsner recently shipped its' first Model GWR-760 high speed fully automatic Wallcoverings Rewinder with the Model OW-30-C Shrink Film Roll Overwrapper to a European customer. The New GWR-760 incorporates features of the companies existing high speed Rewinders used for lighter weight papers and films with new, heavy duty rotary cut-off knife and rolling head systems to better handle the heavy...

Read More »

Automation System produces cable assemblies.

Built from modular components, TransferModule 6000 includes cable transport system, transfer shuttles, transfer chain, cable loading/unloading stations, control system, and PC-based user interface. Stations can perform stripping, tinning, sealing, shield flaring, and micro-flame soldering, as well as ultrasonic and resistance welding, connector housing insertion, and electrical testing. Typical...

Read More »

Reducing Risk Through On-Demand Manufacturing

Check out this white paper to learn how putting manufacturing safeguards in place stimulates growth and reduces risk in your supply chain.

Read More »

System dries samples and allows color viewing.

Designed to help accurately match colors, Dry-N-View includes both Viewing Station and Drying System. Viewing Station comes with Daytime, Incandescent, and Fluorescent light sources for viewing color samples in various settings. Able to dry multiple samples with push of button, low-heat drying system will not distort samples due to intense heat, ensuring accurate color sample results. System...

Read More »

CrankPro-® System for Heat Treating Crankshafts

The CrankProÃ-® system is a non-rotational induction hardening and tempering machine that utilizes advanced SHarP-C(TM) technology. SHarP-C(TM) technology eliminates the rotation of the crankshaft and movement of the inductor during heating and quenching cycles. This stationary heating method provides several practical and technical benefits; reduced floor space, simple operation, robust...

Read More »

Big Kaiser Showcases the Newest in Tooling Solutions at Westec Booth #2632

January 16, 2009 Elk Grove Village, IL - BIG Kaiser Precision Tooling Inc. will showcase a number of new and exciting products at Westec 2009. Visit BIG Kaiser at Booth #2632 to see what's new from BIG Daishowa, Kaiser, Sphinx, Speroni, Unilock and more. BIG Kaiser's EWB-UP (Ultra Precision) Finish Boring Head is a revolutionary new series of Kaiser boring tools with the distinction of the finest...

Read More »

Double Miter Saw suits small/large molding applications.

Developed for precision cutting and producing perfect miter corner joints, Inmes IM-350 employs two 350 mm blades capable of cutting up to 8-¼ x 4 1/8 in. molding at 45-°. Cable-activated adjustable molding clamps securely hold molding during cutting, and 2 dust ports on rear facilitate connection to collection system. Featuring 2 heavy-duty 2 hp motors that turn saw blades at 4,450 rpm, saw...

Read More »Foam Processing System features hydraulic operation.

Designed for precision dispensing, Reactor IPH-25 In-Plant Foam Processing System offers flow rate of 25 lb/min and features 15.3 kW heaters, making it suited for high viscosity materials. System measures volume of material poured and provides repeatability for consistent parts production. Local control module allows up to 25 programmable shot settings and 5 shot sequences. Applications include...

Read More »

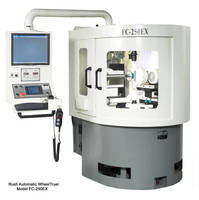

Machines process diamond/CBN wheels for grinding systems.

Designed for processing flats, angles, and radii on diamond/CBN single wheels and multiple wheel packs, Models FC-250EX and FC-700EX Automatic Diamond and CBN Wheel Truing and Dressing Machines feature PLC-controlled, automatic dressing cycles with servo-driven dressing wheel infeed, power swing, and oscillation. With wheel diameters up to 28 in., other features include ExVision, a...

Read More »

Precision Machining Solutions with Over 25 Years of Experience

Quality, customer service, and unbeatable value are the hallmarks of Hogge Precision. Since 1989 we have built a reputation as the go-to precision machining source, servicing many demanding industries. For CNC machining and screw machining, there are few manufacturers that can match our capabilities and expertise. See our video to learn more.

Read More »