Small Angle Grinders offer no-load speeds up to 10,000 rpm.

Equipped with 12 A, 1,490 W motor, Small Angle Grinders include Constant Power Technology and Overload Limit Protection to protect against overheating, as well as Electronic Shut-Off, which shuts down grinder when wheel is stalled. Airflow system features debris baffles and L-shape intake vents, which protect motor and other internal components by blocking debris particles. Multi-Port Exhaust...

Read More »Dynafile Air-Powered Abrasive Belt Machine Replaces Tedious Hand Filing and Sanding

The Dynafile abrasive belt machine grinds, deburrs, blends and finishes normally inaccessible areas on metal, plastic, fiberglass and other composites. Light corner weld removal and blending of welds are typical applications of this tool. The patented abrasive belt tracking system built into every Dynafile provides trouble-free operation. Over thirty different interchangeable contact arms are...

Read More »

Angle Grinder handles granite, marble, concrete, and metal.

Model E9-125 Quick 5 in. angle grinder features vario constamatic (VC) electronic speed stabilization, which monitors motor current and adds voltage as load increases, optimizing running speed. Unit provides 950 W of power and 22 lb-in. torque, with power interruption protection. At 5.4 lb, it is protected from dust/debris and has side handle absorbing up to 60% of vibration. Soft start,...

Read More »

Grinding Center features 12-pocket automatic tool changer.

Designed for grinding, milling, drilling and probing, multi-axis grinding center, Huffman HS-225GC is available in 4, 5, or 6 axis configurations. Grinding spindle has HSK-100 interface, and is available with up to 50 hp(continuous duty) and 4,000-8,000 rpm. Wheel truing devices and spindle motors enable system to use variety of wheels-including electroplated CBN/vitrified CBN/conventional...

Read More »

TOP 3 SEAL TROUBLE SIGNS and HOW TO FIX IT

If ignored, broken seals can lead to a loss in production and equipment shut down. For more information on seals and seal repairs, download now.

Read More »

Candy Granulizer delivers low temperature size reduction.

Using cracking action, IMD 99 Candy Gran-U-Lizer(TM) breaks candy into pieces without high speed impact or high shear, resulting in narrow particle size distributions with minimum of unwanted fines. Due to minimal heat generation, granulizer eliminates problems of smearing or coating of cutting surfaces and allows for steady-state, accurate sizing of heat sensitive or low melting point products.

Read More »

Gear Grinding Machine enables high-speed processing.

Used to grind internally toothed ring gears, ZI20A optimizes grinding speed (sliding velocity) via barrel-shaped and multi-threaded grinding wheel, made of cubic boron nitride (cBN), attached to main spindle. This method enables grinding by high-speed rotation of multi-threaded type grinder wheel. Rotation synchronous control technology achieves grinding speeds through spindle rotations: 15,000...

Read More »Angle Grinder features electronic speed stabilization.

Weighing 6.2 lb, 5 in. Stone Master WE14-125VS suits grinding, cutting, and finishing of granite, marble, or concrete countertops as well as grinding and finishing of specialty metals. Features include soft start, CoolFlow technology for unrestricted airflow, aluminum die-cast housing, and secure racket grip and dual grip zones for ergonomic handling. Motor offers 12.2 A and 1,400 W of power and...

Read More »Angle Grinder features 12.2 A motor.

Weighing just 6.3 lb, WE14-150 Quick 6 in. suits heavy duty cutting and grinding applications in metal working and mechanical maintenance industries. It offers 1,400 W of power, 31 in.-lb of torque and no-load speed of 9,000 rpm. It comes with wheel guard, inner flange, and flange kit for mounting both type 1 and type 27 wheels. Other features included are encapsulated on/off switch,...

Read More »

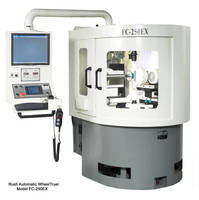

Machines process diamond/CBN wheels for grinding systems.

Designed for processing flats, angles, and radii on diamond/CBN single wheels and multiple wheel packs, Models FC-250EX and FC-700EX Automatic Diamond and CBN Wheel Truing and Dressing Machines feature PLC-controlled, automatic dressing cycles with servo-driven dressing wheel infeed, power swing, and oscillation. With wheel diameters up to 28 in., other features include ExVision, a...

Read More »

Abrasive Belt Machine also converts to die grinder/drill.

Featuring grinding head that pivots 360Ã-

Read More »

Error Proofing by Design

Sturtevant Richmont's torque tools help customers cut rework and warranty costs while increasing throughput.

Read More »