Crack Tester enables 100% on-line inspection.

Zetec InSight CT Eddy Current Crack Tester provides non-destructive detection of cracks or imperfections in critical components at production line speeds. It supports up to 8 dual frequency probes working from 5-10 MHz with sampling rate up to 10,000 samples/sec. Unit can communicate with other machinery via built-in industrial I/O. Data can be downloaded via RS232 serial port, Ethernet...

Read More »

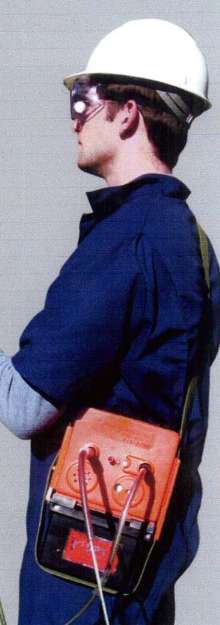

Shoulder-Held Holiday Detector works with all coatings.

Model 915 and 925 SPYÃ-® holiday detectors feature infinite voltage settings over 1,000-5,000 V range, enabling units to be fine-tuned for inspection of any coating thickness. Selection of attachable electrodes facilitates inspections in tanks or vessels as well as on flat and irregular surfaces. Standard wand lengths provide 30 in. reach, and battery lasts for one day of operation without...

Read More »

Optical Module finds micron-sized surface defects.

Featuring integrated line scan camera and LED light source, Micro Ranger(TM) detects extremely small surface defects including three dimensional flaws and subtle variations in surface texture. Camera and light are mounted coaxially in enclosure that maintains precise alignment between all active components. Multiple Micro Ranger(TM) modules can be connected together in network to inspect...

Read More »

Pinhole Detectors utilize wet sponge method.

ElcometerÃ-® 270 Series of holiday detectors features automatic voltage calibration and voltage checks along with low battery indicator and visual and audio alarm. It provides integral and separate wand functionality and is available in 4 model variants. Featuring easy release, snag proof cables, product is compatible with fully interchangeable wand accessories.

Read More »

How to Choose the Right Label for Your Application

This ebook discusses factors to consider when choosing the optimal label for your application.

Read More »

Holiday Detector features roller design.

SPYÃ-® Model 670 speeds inspections of paint, epoxy, and coatings ranging from 1-20 mils. Handheld, self-contained unit eliminates need for belts, clips, and wires. Roller sponge width options up to 24 in. are available, as well as extensions to simplify full range of inspections. Coatings as thin as 1 mil can be inspected with pinhole accuracy and without harm to coating. Single standard 9 V...

Read More »

Weld Seam Detector handles tubes from 5-500 mm dia.

Combining digital signal analysis and eddy current technology, PC-based Model SND40 offers graphical user interface with touchscreen, as well as Fieldbus and Ethernet interfaces. It is suitable for tubes made of all metals and is largely independent of tube wall thickness. Detector handles difficult positioning tasks in tube bending machines, hydroforming presses, and other tube processing...

Read More »

Flaw Detection System uses volumetric grid scanning.

Featuring UT probes, CCD video camera for V-Scan grid positioning, and industrial notebook PC with software, ShafTestÃ-® portable ultrasonic system provides repeatable in-situ testing of shafts and axles. Software highlights cracks and provides tools to plot ultrasonic cross-sections through shaft at any depth chosen by operator. System requires only shaft-end access, avoiding equipment...

Read More »

Holiday Detector enables non-destructive coating inspection.

SPYÃ-® Model 670 incorporates wetted flat or roller sponge as electrode to detect holidays with pinhole accuracy, reducing inspection time for large, flat surface areas. Powered by 9 V battery, unit weighs 3 lb and detects coating defects as thin as 1 mil. When holiday is found, signal light and horn are emitted. Water is used as conductor on sponges for coatings from 1-10 mil. Non-foaming...

Read More »

Corrosion Detection Transmitters offer real-time monitoring.

Corrosion Detection Transmitters allow user to monitor, online, effectiveness of corrosion inhibitors, and to detect and correct corrosion issues through preventive maintenance. They feature 2-wire, loop-powered, 4-20 mA signal with HART protocol. Suited for direct or remote mounting, transmitters can be located in general-purpose and hazardous locations. Probes are available in various styles...

Read More »Inspection System detects small web defects in real-time.

FLAW SCAN SYSTEM detects 0.3mmÃ-² defects on 2 m wide webs, running at 200 m/min. It contains embedded hardware and software with i2S technology for real-time defect detection on continuous web products. Features include real-time display and roll-map, statistical analysis of defect content, and power defect classification tool. Programmable alarm settings are offered for each defect class....

Read More »

560 and 572 Series IP67 Waterproof Inline Plug and Socket Connectors with Shock and Vibration Resistance

EDAC's new line of IP67 waterproof plug and socket connectors represent the cutting edge of waterproof connection technology. Part of the 560 and 572 series of connectors, they utilize innovative design concepts to deliver a level of performance and value that is unmatched in the industry. See our video to learn more.

Read More »