High Speed Applicator handles difficult coatings.

Made of stainless steel/TeflonÃ-®, TurboDisk2 Rotary Atomizer is virtually impenetrable to all fluids. It features serrated edge design and dual feed fluid system. High flow regulators and fluid valves allow for simultaneous paint push out while solvent washes feed tube and disk. Fluid section can be exchanged in minimal time due to quick disconnect features. TurboDisk2 is suited for wide...

Read More »

Conveyorized Coater/Dryer offers speeds up to 20 ipm.

Model 4246 dip coater and infrared dryer system dip coats printed circuit boards in protective conformal coatings, and dries coatings at rates between 2-20 ipm. Stainless steel dip tank includes recirculation and filtration system to maintain quality of conformal coating. Dryer section consists of 6 Glenro Radplane(TM) Series 36 low-temperature electric infrared heaters, which are regulated in...

Read More »

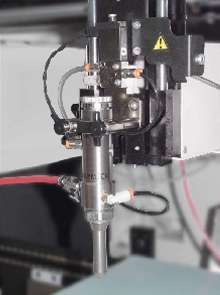

Conformal Coating Applicator offers 3 modes of operation.

Model SC-300 Swirl Coat(TM) allows application of conformal coatings to circuit boards in bead, monofilament, and swirl operation modes with variable dispensing pressure, volume, and shape of air assist. It applies solvent-based and 100% solids coatings with viscosities from 30-3,500 cp. Exposed, zero cavity nozzle design reduces clogging, while low fluid pressure and fine control of film...

Read More »

A Complete Guide to Fabricating Custom Components

This white paper provides an in-depth guide to fabricating custom components.

Read More »

Epoxy Coating System cures at elevated or room temperatures.

The E958-12A Epoxykits, pre-measured, 2-component epoxy coating system, allows for mixing of both components within provided package. Coating cures tack-free in 4-8 hr and obtains complete cure after 96 hr at room temperature. Product may also be fully cured in 5 min at temperatures of 212Ã-

Read More »

Coating System applies thin films to flat substrates.

Prism(TM) 100 utilizes Ultra-SprayÃ-® ultrasonic technology for control of coating quality and thickness. Substrate moves in defined increments while spray head moves transversely to apply coating. System works with liquids from low-viscosity fluxes and solvents to viscous adhesives, conformal coatings, conductive inks, and photo imageable materials. It has 18 x 18 in. spray application area...

Read More »

Extrusion Coating Machine suits short production runs.

Flex-Master 1300 extrusion coating machine handles runs of 1-2 hr for flexible packaging structures, including LDPE, LLDPE, m-LLDPE, Surlyn, and EVA. Coating speed is up to 300 m/min for 1000 mm dia finished rolls. The 65 and 75 mm co-extrusion stations use feed-block and 1500 mm die with internal deckles. Three-roll laminator has linear-nip arrangement, 450 to 760 mm chill roll, 200 mm...

Read More »

Embedding Station uses modular components.

Model EG1150 incorporates EG1150 C cold plate with cooling surface that accommodates 70 molds, and EG1150 H heated paraffin dispensing module, which offers programmable feature for working times and temperatures, 3-liter paraffin reservoir and adjustable dispensing flow rate. System includes 2 heated, removable paraffin waste trays, and removable and interchangeable cassettes and mold warmer....

Read More »

Cable-Coating Systems precisely apply talcs and powders.

Series ECC 700 fluidizes, charges, and sprays cable with various powders, including talcs and super-absorbent powders. Pumps maintain adjustable, even flow of powder to obtain desired coating thickness. Closed-loop powder recovery feature prevents powder from being released into environment. TribomaticÃ-® spray gun charge results from friction between powder and inner surface of gun, while...

Read More »

Spin Coat Systems coat materials on planar substrates.

Spincoat G3 Series incorporates microprocessor-based, closed loop servomotor control for speed regulation. Units include 8, 12, and 15 in. bowl models in 3 enclosure sizes. Eight in. model is available in non-programmable and programmable versions, while 12 and 15 in. models are available as programmable units only. Programmable units can store and execute 30 programs having up to 20 individual...

Read More »

Error Proofing by Design

Sturtevant Richmont's torque tools help customers cut rework and warranty costs while increasing throughput.

Read More »