Machine treats resin to promote surface preparation.

Used in rotational molding, injection molding, or higher-volume applications such as painted automotive parts, RTS Technology allows common resins to be treated while in powder form to facilitate part decoration. It makes parts made of polyethylene, polypropylene, and thermoplastic olefins ready to accept paint, adhesives, and other decorations. Able to treat 2,000-4,000 lb of resin/hr,...

Read More »

Processing System suits optical/industrial applications.

Designed to produce wear-resistant coatings, system offers 3 fundamental deposition techniques: RF Plasma with rotating stage, magnetron for sputtering metals and oxides, and ion beam for direct deposition of DLC and SiO2. It is available in batch and automated load-lock options and features etching capabilities. Able to produce protective, ultrasmooth DLC coatings, system is suited for use in...

Read More »Robot Powder Applicator suits automotive applications.

Designed for automotive exterior and interior cut-in applications, RPA-1 powder gun provides bell-like performance features such as uniform film build and transfer efficiency. It atomizes with no moving parts and simplifies automation controls while minimizing number of robots and atomizers. Simplified design eliminates rotating parts and eliminates defects caused from impact fusion.

Read More »

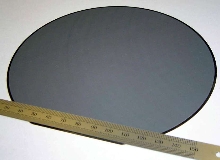

Backside Wafer Coating is enabled by mass imaging platform.

High-throughput backside wafer coating process is capable of exceeding the Ã-

Read More »

Advanced Optics Used in the Medical Diagnostics & Life Sciences

Considerations, challenges, and customized solutions for manufacturing optics in the medical diagnostics and life sciences fields.

Read More »

Optical Variable Device offers brand protection.

DigiVU OVD is applied to metallic substrates and is activated by laser source to form hologram-type image, enabling manufacturers to communicate brand identity and keep it secure from counterfeiters. Chemistry can also be added to Masterbatch in polymer coating over metal, guaranteeing absolute image permanence and resistance to abrasion. Once substrate is treated with DigiVU, image does not have...

Read More »

Black Oxide System finishes heat-treated fasteners.

TRU TEMPÃ-® produces non-dimensional black oxide finish, directly over light heat treat scale, on all types of fasteners and other bulk-handled parts. Since it operates at 200Ã-

Read More »

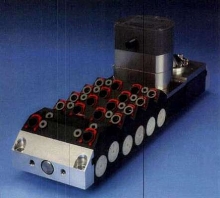

Color Change System features insert-and-seal design.

Modular Color Change System, Model MCV2 is intended for use with all coatings, from waterborne high solids to catalyzed materials. Featuring corrosion-resistant, plastic design, system can be configured for up to 32 colors. Insert-and-seal design requires no additional fittings at connection point. Internally ported stack purge/bellwash module eliminates need for additional solvent/air...

Read More »

Vacuum Coating System suits thin film deposition processes.

Designed for production of substrates used in semiconductor, laser, and scientific industries, custom-built TF600 has 600 mm wide coating chamber with vacuum pumping system in rear. Pumping system options include diffusion, turbomolecular, and cryogenic high vacuum pumps as well as XDS 35i dry scroll pump for backing and chamber roughing. Process options include resistance evaporation, electron...

Read More »

Zinc-Epoxy Coating System meets Class B requirements.

Coating system consists of Steel Spec(TM) epoxy primer and Zinc Clad-® II Plus inorganic zinc rich coating and meets slip coefficient performance standards for bolted connections per ASTM and AISC specifications. Zinc Clad II Plus is solvent-based, 3-component, inorganic ethyl silicate coating that dries to handle in 20 minutes at 77-°F. Corrosion-resistant Steel-Spec topcoat can be applied at...

Read More »

Sputter Coater has 4 in. diameter stage.

Hummer 6.6 facilitates coating of samples prior to scanning electron microscopy. With 4 in. diameter stage, unit accommodates up to 12 SEM pin stubs and up to 100 mm dia substrates.

Read More »

High or Low Volume Custom Crates and Boxes Available from Reid Packaging

Reid provides mil-spec crates and corrugated boxes in custom dimensions from single to triple wall and will even package them on-site. Check out the video to learn more.

Read More »