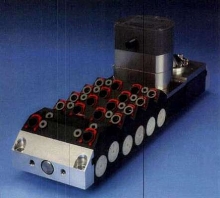

Color Change System features insert-and-seal design.

Share:

Press Release Summary:

Modular Color Change System, Model MCV2 is intended for use with all coatings, from waterborne high solids to catalyzed materials. Featuring corrosion-resistant, plastic design, system can be configured for up to 32 colors. Insert-and-seal design requires no additional fittings at connection point. Internally ported stack purge/bellwash module eliminates need for additional solvent/air connections.

Modular Color Change System, Model MCV2 is intended for use with all coatings, from waterborne high solids to catalyzed materials. Featuring corrosion-resistant, plastic design, system can be configured for up to 32 colors. Insert-and-seal design requires no additional fittings at connection point. Internally ported stack purge/bellwash module eliminates need for additional solvent/air connections.Original Press Release:

Color Change Modules Designed For Today's Applications

The ITW Ransburg MCV2 Modular Color Change System is designed to meet today's rapidly changing world of coatings. With it's modular design and new "insert-and-seal" feature, the MCV2 provides quick and easy color change. Plus, the MCV2 is built on a the Ransburg color valve platform that has become the best in the industry.

Designed for use with all of today's coatings, from waterborne high solids, to catalyzed materials, the MCV2 can handle it all. Plus, the MCV2 allows for changing needs of fluid supply systems and has the ability to expand as the needs of a system change.

The MCV2's low profile makes it ideal for applications where space and weight are a premium, such as robot applications. And it can be configured for up to 32 colors, allowing for a variety of quick and easy color changes. It's lightweight plastic design is durable, corrosion resistant and built to last under rigorous and continuous use.

The products unique "insert-and-seal" design means that no more additional fittings are required at the connection point, eliminating the cost of the fittings and the labor to install. In addition, the products internally ported stack purge/bellwash module eliminates the needs for additional solvent/air connections.

ITW Ransburg Electrostatic Systems, an Illinois Tool Works Company, offers variety of finishing products and systems, including electrostatic systems, electrostatic HVLP systems, automatic sprayguns, disks and bells, gun reciprocators, closed-loop fluid control systems, and system parts and accessories. Harold Ransburg first experimented with paint charging and surface grounding technologies in the 1930s, and patented the revolutionary electrostatic finishing process in 1941. Today, ITW Ransburg remains an industry innovator and serves the global liquid electrostatic spray-finishing marketplace from the headquarters in Toledo, Ohio.