Methods Named Exclusive North American Importer of Feeler Machine Tools

Announcement coincides with Introduction of All-New Line of High Performance Machine Tools. Sudbury, MA, U.S.A. - Methods Machine Tools, Inc., a leading supplier of innovative precision machine tools, has announced effective today, that they are the exclusive importer of Fair Friend Group's (FFG) FEELER line of machine tools throughout North America. FFG (Taipei, Taiwan) is one of the largest...

Read More »

Universal Machining Center offers 5-axis, 5-side contouring.

Model U5-3000 system features Y-axis travel of over 20 ft, unlimited X-axis travel, and Z-axis ram with 20 in. cross section. Its 15,000 rpm contouring spindle delivers up to 42 lb-ft torque, while rigid box-way roller-bearing rail system and dual-motor rack-and-pinion X-axis drive offer precision and high thrust levels on long-travel cuts. System has feed rates up to 787 ipm, with continuous...

Read More »

Vertical Machining Center handles large workpieces.

Accommodating up to 5,500 lb on 59.1 x 31.5 in. work table, Model FJV-35/60 II comes equipped with 50 taper, 40 hp, 10,000 rpm spindle that generates up to 433 lb-ft of torque for cutting large cast iron, steel, and aluminum workpieces. Double column machine utilizes roller guides on all axes for feedrates of 1,574 rpm in X- and Y-axes and 1,181 ipm in Z-axis. Featuring 12 in. LCD color display...

Read More »

CNC Machining Center features large work envelope.

Designed for machining products such as mold layups and thermoformed parts, RAM-Z style CNC machining center offers up to 48 in. of gantry clearance and stroke. Available features include automatic tool changing components, up to 20 hp spindles, and 3- or 4-axis (simultaneous) configurations. Oversize gantry supports ride on dual 35 mm linear bearings on each side of tubular steel frame, and...

Read More »

Makers Nutrition: Choosing the Optimal Supplement Manufacturer

This white paper provides and overview into choosing the optimal supplement manufacturer. Establishing your nutraceuticals company is a multi-faceted project.

Read More »

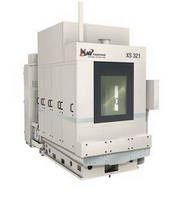

Machining Center offers adjustable design for various tasks.

Machining Center XS 321 is available as XS 321 Basic Machine for operations such as drilling mounting holes, tapping holes, and drilling oil holes on cylinder head. It includes economic work spindle that can turn at speeds of 10,000, 12,000, or 16,000 rpm. Utilizing high-torque work spindle, XS 321 Heavy Machining model has high power drive units on X and Z axes and is suited for drilling...

Read More »Vertical Manufacturing System adapts to changing requirements.

Designed as console-type, cross-operated pick-up machine, Model VLC 250 features 250 mm chuck and can be individually configured to meet machining requirements. Recirculating conveyor transports workpieces to pick-up position, where they are taken up by chuck. To check workpiece tolerances, measuring probe can be integrated into process. Modular design enables choice of 4 different spindles,...

Read More »

Automated Machining Center suits small parts manufacturing.

Able to access 5 sides of part and complete it in single set-up, M8 five-axis, high-speed, trunnion machining center incorporates robotic interface and pick-and-place system for automated manufacturing. Steel bridge reinforced with polymer concrete provides stability and support. Spindle options include 2 kW, water-chilled, 60,000 rpm spindle and 3 kW, 40,000 rpm, HSK-E 25 spindle, both with...

Read More »

Multiaxis HMC is suited for machining complex parts.

Able to handle composites, titanium, and aluminum, E Mill is designed for machining small cross-section parts up to 39.4 ft long in aerospace, construction, shipbuilding, and wind power industries. It comes with 16,000 or 24,000 rpm spindle and performs contour machining/routing/drilling/tapping to produce finished, complex, 3D-geometry parts in one setup. Along with 5 axes of motion, design...

Read More »

OMAX-® to Demonstrate 60120 JetMachining-® Center at EASTEC

Latest combination of OMAX Intelli-MAXÃ-® Software Suite Version 13 and Dual Pump Package offer the fastest precision cutting of extremely complex parts Kent, Washington, March 10, 2009 - OMAX Corporation's 60120 JetMachining Center will be on display in booth 1029 at EASTEC 2009. The robust precision machining performer will be demonstrated with the OMAX Dual Pump Package, Rotary Axis,...

Read More »

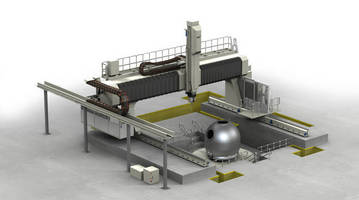

U5 Machining Center Aids Search for Extraterrestrial Life

Mirror for Kepler space telescope machined on MAG five-axis U5 universal machining center. Space craft on three-year mission to search galaxy for Earth-like planets. MAG Cincinnati's bridge-type U5 machining center demonstrated its accuracy and versatility by helping to produce the 1.4 m (4.5 ft) glass mirror for the recently-launched Kepler telescope. The three-year mission of the Kepler...

Read More »

What Can Test Devices Spin for You?

Test Devices helps you ensure the safety and efficiency of your high performance machines with cutting edge spin testing, rotor engineering, and precision balancing capabilities. Check out the video to learn more.

Read More »