Machining Center offers adjustable design for various tasks.

Share:

Press Release Summary:

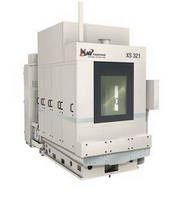

Machining Center XS 321 is available as XS 321 Basic Machine for operations such as drilling mounting holes, tapping holes, and drilling oil holes on cylinder head. It includes economic work spindle that can turn at speeds of 10,000, 12,000, or 16,000 rpm. Utilizing high-torque work spindle, XS 321 Heavy Machining model has high power drive units on X and Z axes and is suited for drilling camshaft bearing bore or milling combustion chamber surface area at cylinder head.

Original Press Release:

High Performance Machining Center XS 321

Lean production is a specific customer requirement that demands an optimal price-performance ratio. The new XS 321 machining center concept sees MAG Powertrain setting new standards in this field. Our engineers have developed a production concept that meets the highest technological demands at very low costs.

The XS 321 is the big sister to the XS 211 that was launched in 2004. The basis for this concept is the creation of a customer - oriented series of machining centers which must offer a high level of modularity that can be both easily and flexibly adjusted to various tasks.

To optimally meet these requirements, the XS 321 will be available in two versions.

XS 321 Basic Machine

For simple machining operations such as drilling mounting holes, tapping holes and drilling oil holes on a cylinder head, the XS 321 is fitted with an economic work spindle that can turn at speeds of 10,000 rpm, 12,000 rpm or 16,000 rpm (HSK 63).

XS 321 Heavy Machining

A high-torque work spindle with HSK 100 is used in the XS 321 for demanding operations such as drilling the camshaft bearing bore or milling the combustion chamber surface area at the cylinder head. Higher power drive units are also deployed for the X and Z axes.

The benefit of such a flexible machine adjustment is that different versions of the same machine can be used in a single project for various machining operations. The XS 321 can thus be used for both heavy machining and finishing operations. Another plus is the range of tool magazine variants and the machine loading concepts. They enable highly accurate adjustment of both the machine and the process to the specific requirements of the customer. The option to retrofit a variety of modules also guarantees a high level of investment security.