Universal Machining Center offers 5-axis, 5-side contouring.

Share:

Press Release Summary:

Model U5-3000 system features Y-axis travel of over 20 ft, unlimited X-axis travel, and Z-axis ram with 20 in. cross section. Its 15,000 rpm contouring spindle delivers up to 42 lb-ft torque, while rigid box-way roller-bearing rail system and dual-motor rack-and-pinion X-axis drive offer precision and high thrust levels on long-travel cuts. System has feed rates up to 787 ipm, with continuous C-axis to keep spindle in-cut without running out of C-axis travel or waiting for axis to unwind.

Original Press Release:

Massive Mill "Goes Deep" with 3-Meter Z Axis for Large Aluminum and Composite Parts

New 5-axis U5-3000 Universal Machining Center brings lean processing to huge aluminum and composite parts with 3-meter Z, 6-meter Y and unlimited X axis ranges

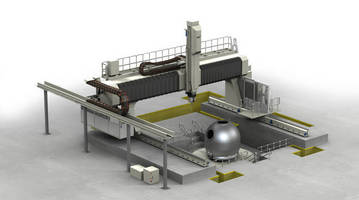

MAG's new U5-3000 Universal Machining Center combines massive platform capacity with long-reach 3-meter Z-axis and 5-axis, 5-side contour machining for efficient processing of "really big" aluminum and composite parts. Newest addition to the U5 family of gantry mills, the U5-3000 is engineered to machine at extreme limits and into deep cavities of large prismatic parts. Combined with Y-axis travel of over 6 meters (20 ft), unlimited X-axis travel, and high-speed, 15,000-rpm, 5-axis spindle, the U5-3000 brings never-before-possible machining efficiencies to extremely tall, wide and long parts. Its exceptional capacity provides versatility to large-part machining for aerospace, energy, marine, and die/mold applications.

Engineered by the global leader in large aluminum machining systems, the U5-3000's modular, heavy-duty gantry design delivers the stiffness, range and performance to machine complex part geometries with exceptional accuracy. A rigid box-way roller-bearing rail system and dual-motor rack-and-pinion X-axis drive provide smooth precise movement and high thrust levels on long-travel cuts. Feedrates up to 20 m/min (787 ipm) optimize processing efficiencies on large part surfaces.

Five-axis/five-side processing allows manufacturers to machine more part features in a single setup for lean efficiencies and higher productivity, while reducing potential errors caused by multiple setups on high-value parts. The U5-3000 comes standard with a 15,000-rpm, 30-kW (40.2 hp), HSK63A gimbal-style contouring spindle that delivers up to 57 Nm (42 lb-ft) torque for high-speed, high-throughput cutting performance. As options, 20,000-rpm and 24,000-rpm 5-axis spindles are available. The 5-axis head features continuous C-axis to keep the spindle in-cut without running out of C-axis travel or waiting for C-axis to unwind. A rigid Z-axis ram with 508 mm (20 in) cross section provides high rigidity for superior precision and surface finish, especially with longer tools and extended Z-axis reach. Flood and through-spindle coolant keep cutting zones clear, with automatic chip and coolant collection systems available.

Highly customizable to application requirements, the U5-3000 can be field-expanded in the X-axis in 3.7 m (12 ft) increments.

Productivity enhancing options include automatic head change, choice of high-torque or high-speed spindles, and vertical, horizontal and custom designs. Multiple head configurations optimize spindle access to complex and challenging part features. Interchangeable heads help to minimize machine downtime, part reorientations, and setups. Other options include fixed tables, rotary tables and automated pallet shuttles.

About MAG

MAG is a leading machine tool and systems company serving the durable-goods industry worldwide with complete manufacturing solutions. The company offers a comprehensive line of equipment and technologies including process development, automated assembly, turning, milling, automotive powertrain production, composites processing, maintenance, automation and controls, and core components. Key industrial markets served by these technologies include aerospace, automotive and truck, heavy equipment, oil and gas, rail, solar energy, wind turbine production and general machining.

With manufacturing and support operations strategically located worldwide, MAG ranks as a leader in the capital equipment market. A growing number of leading international companies are relying on the impressive innovation power of MAG to assure their technological leadership and prepare for future challenges. For more information about MAG, please visit: www.mag-ias.com.