Glue Gun pumps up to 4 lbs of glue per hour.

HD200 Glue Gun includes multi-Positive Temperature Coefficient heating system for accurate temperature control. Designed for use with 1/2 in. round high-temperature glue sticks, 250 W unit heats to 410Ã-

Read More »

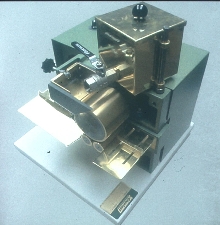

Applicator Head suits high speed applications.

Electromatic XVI Mid Size Applicator Head operates at pressures up to 2,000 psi, and typically fires above 1800 cycles per minute. Internal 24 Vdc or 120 Vdc solenoid coil eliminates need for additional valves, and may be operated by PLC. All wetted parts are stainless steel, with only one moving part and no seals or packings to wear. Applicator head is intended for use with cold adhesives,...

Read More »

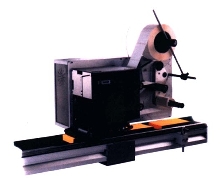

Printer Applicator features 2-line digital display.

Model 3038 offers operator-friendly display with clear and complete error messaging, keypad entry, standard velocity compensation, and multi-page memory. Stainless steel and anodized aluminum construction provides corrosion resistance in hostile environments. Model 3038 is compatible with any OEM printer and is available in variety of stroke lengths.

Read More »

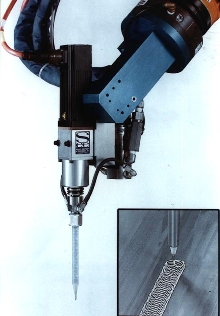

Dispenser creates circular patterns and continuous beads.

Program-A-Swirl(R) maximizes adhesion between 2 substrates, using less material to wet-out greater area. Swirling is achieved when servo motor spins dispenser's nozzle. System can dispense single-component materials, or it can be used with static mixer nozzle for 2-component, reactive-resin materials. It is typically mounted at end-of-arm tool in robotic applications, or fixture-mounted in...

Read More »

Glue Machine applies adhesive without runover.

Electric Top Side Edge Gluer applies adhesive to paper, card, corrugated stock, or binder board quickly and without runover. Machine glues any stock up to 1 in. thick and adjusts the glue film from 1/8 to 3 1/2 in. Adjusting glue film thickness is done by turning knob. It has fully enclosed gear motor, standard motor speed control, and large adhesive reservoir that holds more than 1 gal.

Read More »

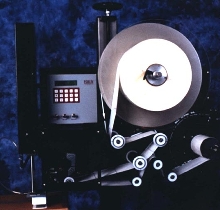

Print/Apply Systems have 64-bit microprocessor.

ALX 924/926 Print-and-Apply Systems offer maximum print speed of 16 ips. They produce 1D and 2D bar codes, graphics, and human-readable copy on range of label materials at 300 dpi print resolutions. The system's 1000-meter ribbon supply permits extended operation without ribbon changes. ALX 924 and 925 have print widths of 4.2 and 5 in., respectively. Both handle label widths up to 5.2 in. ALX...

Read More »

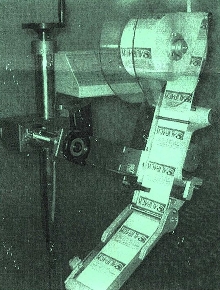

Convertible Labeler offers versatility.

Convertible Labeler changes from label applicator to print and apply labeler in less than 15 minutes. Mini size accommodates 10 in. OD roll of labels and Standard size utilizes 16 in. rolls. Units include centralized keypad, screened label paths, and cantilevered printhead. Label sizes from .75 x .25 in. up to 4.1 x 14 in. can be applied.

Read More »

Can Tab Lubricator cuts oil use, reduces rejects.

MicroCoat(R) lubrication method gives can makers control over amount of oil applied to pull tabs. It lowers lubricant use and reduces residual oil that can migrate from tabs and lids into can contents. It has precision spray valves that use low volume, low pressure (LVLP) air to coat pull tab stock with fine film of oil that keeps dies sharp, eliminates pressroom mist and puddles, and minimizes...

Read More »

Label Applicator does not dirty users' hands.

Fully programmable Tritone 100 label dispenser and applicator can be used in both vertical and horizontal positions. It applies labels with widths to 4 in. and lengths to 14 in. at rates of 1-30 meters/min. Stepper motor controlled Microprocessor control box provides LCD display for memory and change of label parameters. Tritone 100 works with conveyor speeds from 16 to 100 ft. per min.

Read More »

Adhesive System eliminates mixing and metering.

Adhesive system incorporates PAM 500K, 500K Spray, and polyurethane cartridges. It uses compressed air to deliver adhesive at controlled and sustainable rate. Thermometer mounted on applicator allows observation of adhesive temperature. Normal operating temperature ranges are 90 to 325 deg F and 300 to 450 deg F. Common bonding substrates include wood, plastics, rubber, and plasticized vinyls.

Read More »

SpillVak Absorbs Up to 6X More Fluid Than Rock- and Clay-based Absorbents

Are you struggling to find an absorbent that doesn't result in at least some leaching? SpillVak outperforms all rock and clay-based materials. Check out our video to learn more.

Read More »