UNIST, Inc.

Grand Rapids, MI 49512

Coolant/Lubricant Mixing Station can be manual or automatic.

Manual Mixing Station (MM-S) and Central Supply Mixing Station (CSM-S) are designed for blending and dispensing of cutting and forming fluids in manufacturing. Automated mixing and supply of fluids and lubricants to one or more machining or metalforming stations results in consistent concentration ratios. While CSM-S produces concentration ranges from 0.5-37% and delivers up to 3 gpm, MM-S has...

Read More »

Lubrication System delivers thru-tool micro-fluidization.

Designed to retrofit to CNC drilling machines and other coolant-fed drilling applications with coolant inducers, Tornado Thru-the-Tool Lubrication System(TM) permits unrestricted airflow and minimum air pressure drop to cutting tool edge for consistent, precise flow of lubricant throughout cut. Positive displacement system produces total fluid output of 1-100 drops/min and may be connected to...

Read More »Uni-Roller-® Reduces Fluid Consumption by 50% at California Plant

Grand Rapids, MI: Simpson Dura-Vent, the well-known manufacturer of Gas Vent and Chimney Products, has reported a 50% reduction in consumption of stamping and drawing fluids, which they directly attribute to their recent integration of the uni-RollerÃ-® System with the SPR Programmable Controller, at their Vacaville, CA facility. Dura-Vent became a new customer of UNIST, Inc. early in 2005....

Read More »Lubrication Unit features programmable controller.

Designed to fit into small press windows, mini-Roller(TM) coil stock lubrication unit utilizes Model SPR-2000-JR Programmable Lubrication Station as standard supply system. Internally fed mini-Roller delivers precise, uniform fluid coverage to any stock width under 4 in. Controller enables user to control fluid thickness, minimize maintenance, and eliminate need for fluid reclamation. Unit's...

Read More »Positive Displacement System lubricates pneumatic hand tools.

Weighing less than 11 oz when full and measuring 3 in. long without fluid attachments, Mini-Piggy-Back Model 9470 is 100% pneumatic and uses compressed air supplied downstream from tool trigger. Fluid supply is contained in refillable and interchangeable clear cartridge that attaches with quick disconnect fitting. Fluid displacement can be adjusted from 0-.03 cc/min, and atomizing air can be...

Read More »Micro-Fluidization System delivers portable solution.

Uni-Max(TM) Coolubricator(TM) Jr. 210-P serves as entry point for utilizing MQL (minimal quantity lubrication) with high-efficiency lubricants in tool room and production applications. Attached with magnet, cutting tool lubrication system may be moved from machine to machine. It employs adjustable .033 cc/stroke max pump and pneumatic pulse generator for 100 million cycle capability. System is...

Read More »

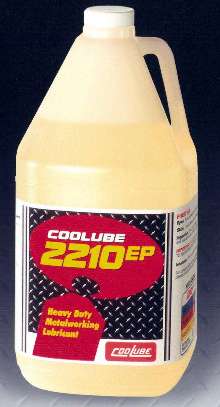

Vegetable-Based Lubricant is suited for use in metal cutting.

Suited for machining of ferrous materials, environmentally safe Coolube 2210EP works with Uni-Max applicators. Extreme pressure additive, blended to Coolube 2210, exhibits lubricity properties which facilitate near dry machining in heavy-duty cutting operations on all CNC, automatic screw, drilling, tapping, milling, turning, and hard turning machines. Product also extends longevity of, and time...

Read More »Unist Announces New Handbook For Machining with MQL

Publication offers an introduction to Minimum Quantity Lubrication basics. Grand Rapids, MI – Unist, Inc. (www.unist.com) Unist, Inc. is pleased to announce the publication of The MQL Handbook, an introduction to machining with Minimum Quantity Lubrication (MQL).Ã- Ã- The publication aims to explain the basic principles behind MQL and to give machinists getting started with MQL the...

Read More »UNIST Announces Vice President of Business Development

Grand Rapids, MI USA: Tim Walker was recently appointed to the newly created position of Vice President of Business Development for UNIST, Inc. Tim's responsibilities as Vice President of Business Development will be multi-faceted with the ultimate goal of increasing both domestic and international sales. His initial focus will be analyzing the current inside and outside sales infrastructure to...

Read More »UNIST, Inc. Has Promoted Mark Cooper to the Position of National Sales Manager of All UNIST Products

Grand Rapids, MI: UNIST, Inc., the well-known manufacturer of lubrication systems which decrease fluid usage and increase productivity in industrial applications, has promoted Mark Cooper to the position of National Sales Manager of all UNIST Products. Mark has been part of the UNIST team for over five years, starting as an inside sales person. For the past two years, his responsibilities have...

Read More »UNIST, Inc. Company Ownership Transition

Grand Rapids, MI: Lubrication system manufacturer, UNIST, Inc., will transition to new ownership beginning January 1, 2008. Chuck Boelkins, son of current owner Wally Boelkins, will be purchasing the company from his father. Formed in 1957, UNIST is a leading manufacturer of fluid delivery systems designed to reduce fluid consumption while improving the operational efficiency of a broad range of...

Read More »2007 Marks the 50th Year of Business for UNIST, Inc

Grand Rapids, MI: GRAND RAPIDS, MICHIGAN: 2007 marks the 50th year of business for UNIST, Inc. - the leader in lubrication technology for metalworking, metalforming, and related industries. UNIST specializes in eliminating excess fluid and lubricant considerations by improving the processes used to apply them. UNIST Systems reduce fluid consumption while enhancing all areas of operational...

Read More »

Coolant/Lubricant Mixing Station can be manual or automatic.

Manual Mixing Station (MM-S) and Central Supply Mixing Station (CSM-S) are designed for blending and dispensing of cutting and forming fluids in manufacturing. Automated mixing and supply of fluids and lubricants to one or more machining or metalforming stations results in consistent concentration ratios. While CSM-S produces concentration ranges from 0.5-37% and delivers up to 3 gpm, MM-S has...

Read More »UNIST Publishes New Metalforming Systems Catalog

Grand Rapids, MI: UNIST, Inc. has published a comprehensive new resource for Metalforming companies. The complete family of Metalforming Lubrication Systems from UNIST, Inc. is now presented in a single, easy to use catalog. Since introducing their first roller system for coil stock lubrication in 1993, UNIST has developed an extensive line of components for use in nearly every type of...

Read More »

Lubrication System delivers thru-tool micro-fluidization.

Designed to retrofit to CNC drilling machines and other coolant-fed drilling applications with coolant inducers, Tornado Thru-the-Tool Lubrication System(TM) permits unrestricted airflow and minimum air pressure drop to cutting tool edge for consistent, precise flow of lubricant throughout cut. Positive displacement system produces total fluid output of 1-100 drops/min and may be connected to...

Read More »Uni-Roller-® Reduces Fluid Consumption by 50% at California Plant

Grand Rapids, MI: Simpson Dura-Vent, the well-known manufacturer of Gas Vent and Chimney Products, has reported a 50% reduction in consumption of stamping and drawing fluids, which they directly attribute to their recent integration of the uni-RollerÃ-® System with the SPR Programmable Controller, at their Vacaville, CA facility. Dura-Vent became a new customer of UNIST, Inc. early in 2005....

Read More »UNIST, Inc. to Present Near Dry Machining at Westec 2006 Comparative Technology Forum

Grand Rapids, MI: UNIST, Inc. has been invited to present Near Dry Machining in a technology forum hosted by the SME (Society of Manufacturing Engineers). The Comparative Technology Forum is part of The SME Summit Conference and Annual Meeting, which will be held at the Westec 2006 Exposition and Conference at the Los Angeles Convention Center March 27-30. UNIST's presentation will take place...

Read More »